2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Show Us How You Use Your Bambu Printer – Win an H2D 3D Printer + Get Featured!

Learn More

Note: This item is unable to be shipped outside the U.S.

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Contact us for detailed purchasing support and custom pricing. A Dynamism 3D Printer specialist will contact you within one business day.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Bambu Lab X1E

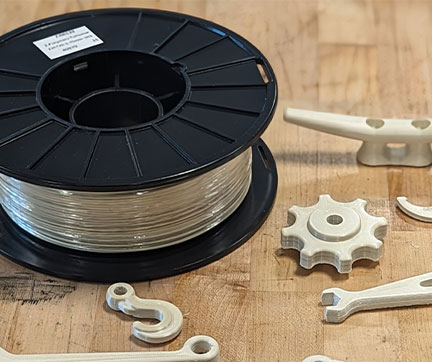

Z Polymers Tullomer - 1kg x 1

Magigoo Pro PC (Polycarbonate) - 50ml Pen x 1

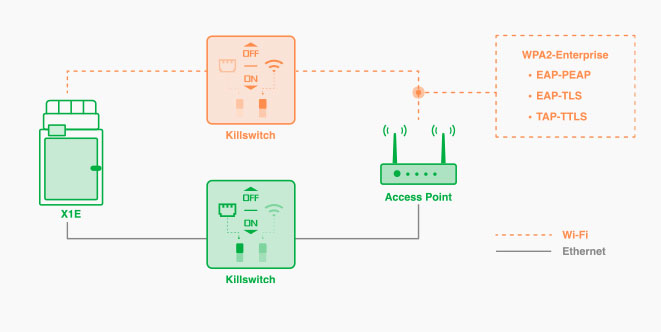

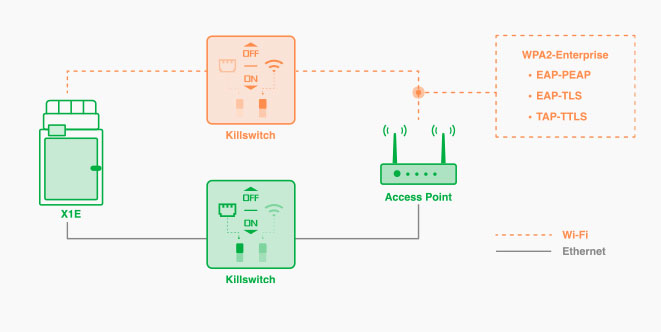

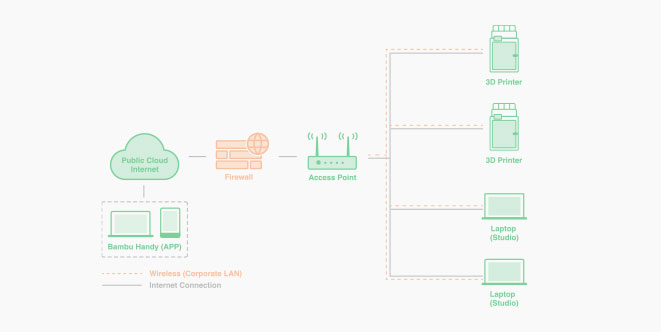

The X1E offers the option to connect to your devices through its newly added Ethernet port, ensuring robust network communication in complex environments. Ethernet connectivity can also be used in crowded wireless signal environments. Additionally, the X1E provides WPA2-Enterprise Wi-Fi Authentication (EAP-PEAP/EAP-TLS/TAP-TTLS) and individual physical kill switches for both Wi-Fi and Ethernet, meeting stringent network security requirements.

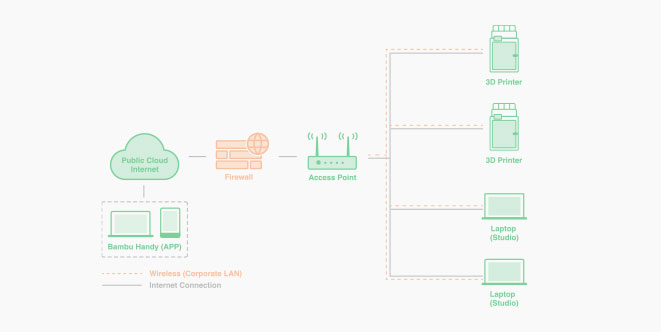

The X1E can operate independently without a connection to Bambu Cloud Service, fully functional within your local network. Customers can remotely control the X1E through LAN communication without requiring an Internet connection.

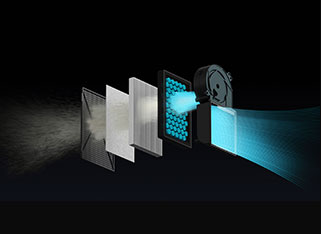

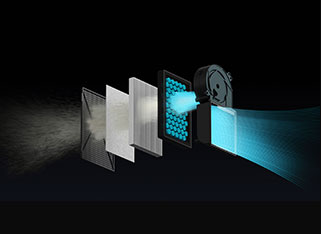

We combined a G3 pre-filter, an H12 HEPA filter, and a high-quality coconut shell activated carbon filter to provide optimal air filtration. Enhanced filtration can effectively reduce excessive odors and particulates when printing in less ventilated environments.

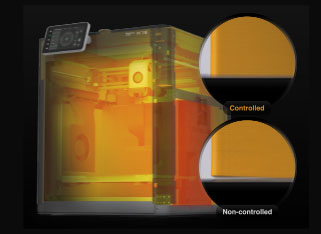

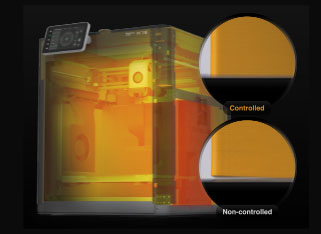

The X1E can actively heat and regulate the chamber temperature. Accurately controlled chamber temperature (up to 60°C or 140°F) improves print quality, especially for filaments prone to warping such as ABS and PC.

Higher nozzle temperature make possible to print higher performance materials such as PPA-CF/GF PPS and PPS-CF. These new materials have better dimensional stability, heat resistance and mechanical performance.

The superior carbon-fiber rods in the CoreXY motion structure enable the X1E to achieve a toolhead acceleration of 20,000 mm/s² by reducing the weight of moving parts. This faster acceleration allows the X1E to maintain its maximum travel speed of 500 mm/s for longer periods, significantly reducing overall print time.

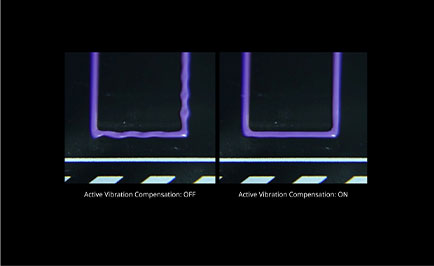

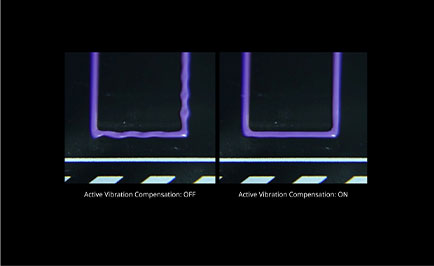

X1E can actively compensate for XY-axis vibrations and extrusion issues to ensure exceptionally smooth print quality. All measurements are fully automatic, eliminating the need for manual adjustments.

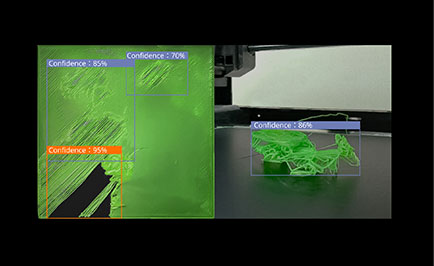

The X1E's AI algorithm can detect first-layer imperfections and spaghetti failures with the assistance of Lidar and computer vision. It then automatically pauses the print to prevent catastrophic failures.

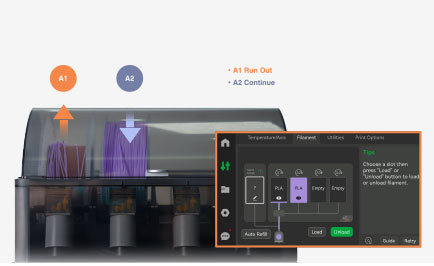

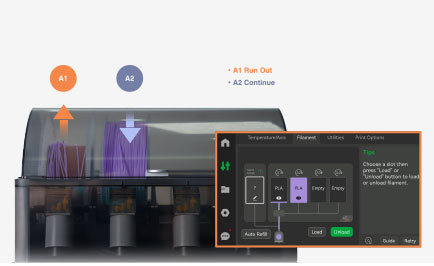

X1E can parallel connect 4 Bambu AMS systems to print with up to 16 spools of filaments, good for printing dedicated support materials for seamless surface and printing multi-color. The AMS system also supports automatic filaments reload, to used up all filament on one spool before switching to the next.

Medical Mesh, Prosthetics, etc.

Aerospace, Ballistics, Tethers, Functional fabrics

Fuel Cells, Automotive Parts, etc.

Magigoo Pro PC is designed to address first layer adhesion to the build platform and print warping with Polycarbonate filaments, making sure prints stick firmly when the print bed is hot and that the part is easy to remove once it cools. This unique and innovative mechanism means that no tools are needed to remove prints from the bed, as they just pop off when the bed cools down.

The strength and toughness of PC make it an ideal FFF material for the production of functional prototypes as well as end use parts, but printing with it does present some challenges. Virgin PC has a high glass transition temperature (Tg) and thus can be used in high temperature applications. However, having a high Tg can make it very difficult to print using desktop printers, as these are usually not equipped as well for the high printing temperatures required to print virgin PC. Virgin PC tends to warp considerably when using an insufficient bed temperature (<130 ºC), or when printed in non-heated enclosed chambers without the use of an appropriate bed adhesive.

Magigoo Pro PC can be used on glass or a multitude of other surfaces. Use on other plastic-based surfaces, including sheets, is recommended to provide strong adhesion and preventing the part from fusing to the sheet.