2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

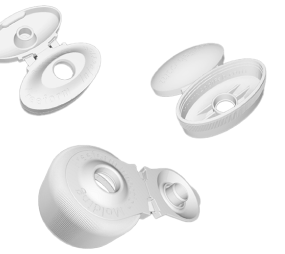

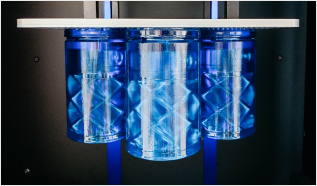

Experience enhanced production flexibility while reducing costs and accelerating lead times. FIM provides a faster, more cost-effective solution for producing parts, particularly for prototypes, small production runs, and custom designs.

Is Your Facility Ready to Embrace the Future of Manufacturing?The Free form Injection Molding process combines the precision of CAD design, the flexibility of 3D printing, and the efficiency of injection molding to produce parts quickly and accurately.

How Free Form Injection Molding Can Improve Your Manufacturing Process

Cut lead times from weeks to days with 3D-printed molds that allow for quick, on-demand iterations.

Reduce expenses by using cost-effective 3D printing for short runs and prototypes, instead of costly traditional molds.

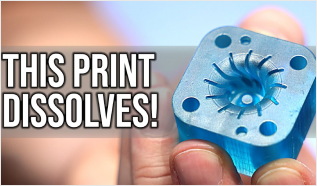

Use precise material amounts and save storage space with dissolvable molds.

Easily create custom and complex designs with FIM.

Total time to injection molded part

Total time to injection molded part

Total time to injection molded part

Reimagines Product Development Workflows with Nexa3D x Addifab

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now