2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Key Features:

Show Us How You Use Your Bambu Printer – Win an H2D 3D Printer + Get Featured!

Learn More

Please Note: This item is unable to be shipped outside the U.S.

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Contact us for detailed purchasing support and custom pricing. A Dynamism 3D Printer specialist will contact you within one business day.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

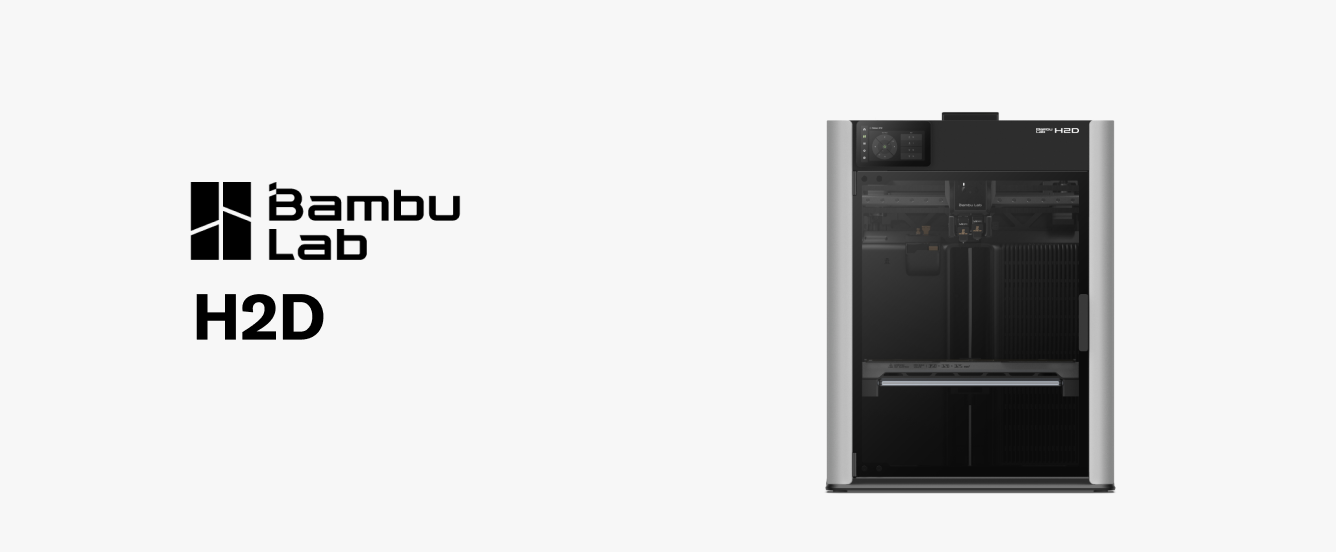

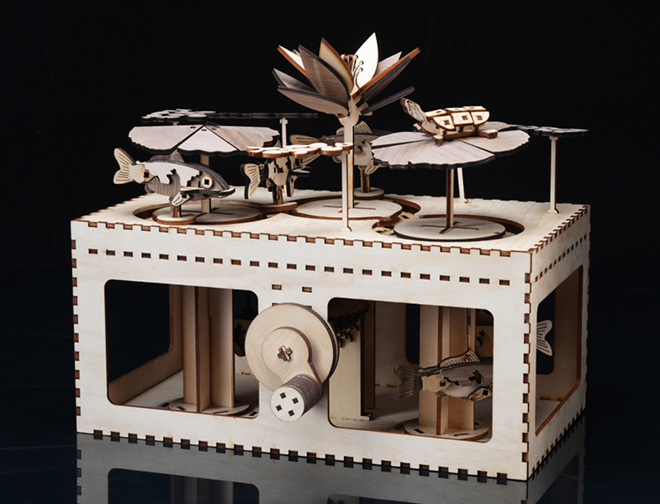

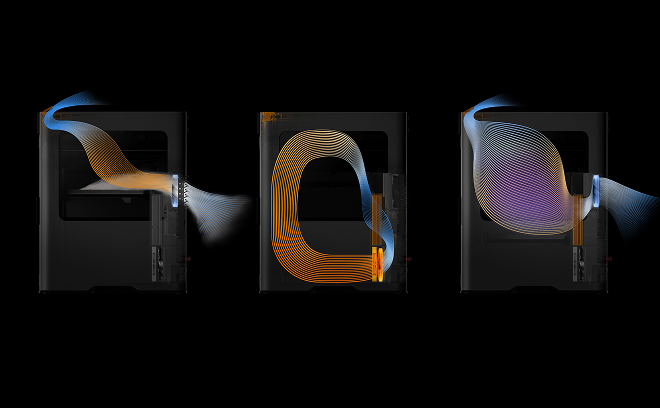

The H2D seamlessly integrates dual-nozzle 3D printing, laser engraving and pen plotting, enabling users to bring their boldest ideas to life.

Expanded design freedom and reduced material waste.

Print flexible and rigid materials in the same project! Create dedicated support structures for perfect overhangs with minimal waste.

Save space and money by combining multiple tools into a single, integrated system.

The H2D is more than just a 3D printer. With optional modules, it becomes a laser engraver and cutter, a digital cutter for materials like vinyl and fabric, and a pen plotter for intricate drawings and artwork.

Expand creative horizons and offer personalized products. Optional add ons available in 10W and 40W modules.

Add intricate details to projects with the powerful laser engraving and cutting capabilities. Engrave on wood, leather, acrylic, and more.

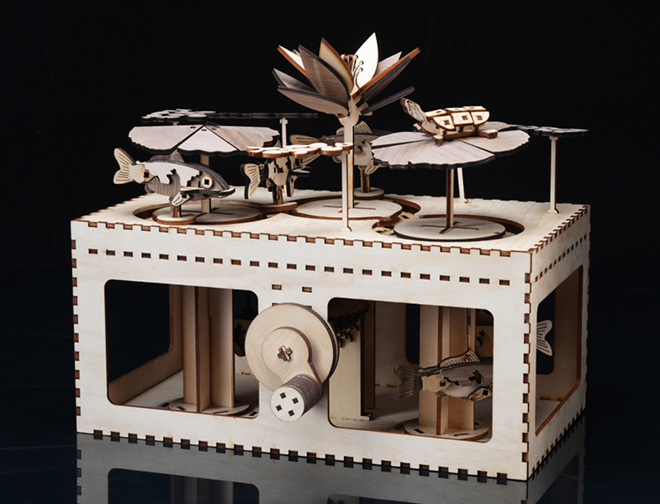

Easily create custom designs with the optional digital cutting module.

Precisely cut a wide variety of materials, including vinyl, paper, fabric, and thin plastics. Create custom stickers, decals, stencils, and more.

Print bigger models, engrave larger objects, and the your most ambitious designs to life.

With a generous build volume of up to 350mm x 320mm x 325mm, the H2D lets users create large-scale projects with ease.

Create strong, durable, and functional parts for demanding applications.

The H2D includes a 350°C hotend and a 65°C actively heated chamber, allowing users to print with high-performance materials like ABS, ASA, PC, and nylon without warping or deformation.

Reliable and consistent printing, even with challenging materials.

The H2D features a filament monitoring system with 15 sensors that track filament flow, tension, and more. Get real-time alerts and prevent print failures due to filament issues.

Minimize waste and maximize resources.

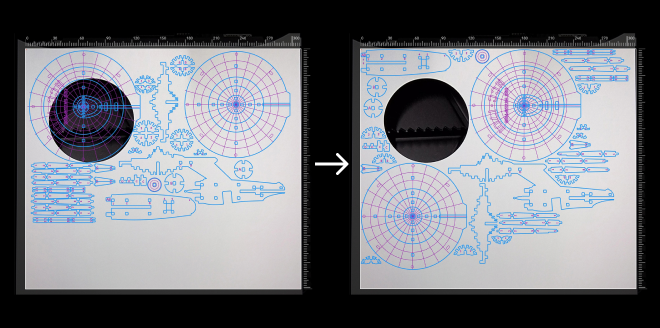

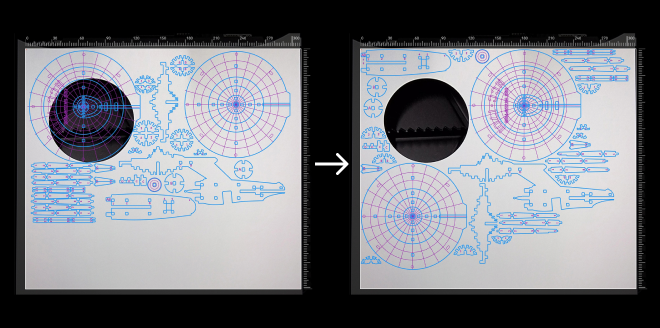

Leveraging real-time images from the BirdsEye camera, Bambu Suite can automatically arrange projects according to the shape of material, i.e left over plywood from the previous project.

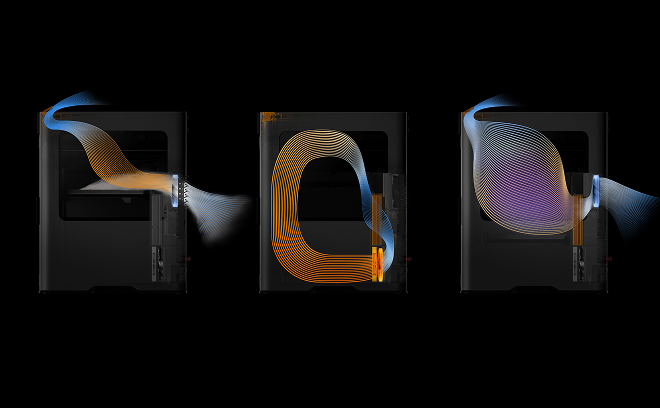

Enhanced safety and optimized performance.

The H2D features comprehensive material flow monitoring. Throughout the AMS-to-nozzle path, 15 strategic sensors form an intelligent network, continuously tracking five key parameters: feeding velocity, tension, filament tip location, extruder thermal environment, and dynamic extrusion pressure.

The H2D laser full combo has a built-in air pump and air pipe on the back of the printer, and is pre-installed with a BirdsEye camera. The front door, left and right side Laser Protective Windows, and top cover are all designed with laser protection. The packaging list includes a laser module, a cutting module, a smoke exhaust pipe and its adapter, as well as an emergency stop button.

We plan to launch a laser upgrade kit for the non-laser version of H2D. The upgrade kit is expected to be released in June and will also provide installation instructional videos to help users complete the upgrade smoothly.

It is important to note that the air pump in the upgrade kit is an external air pump, which has a different installation structure from the built-in air pump in the full set. When using it, it can only be installed externally and connected to the machine through an air tube.

Yes, the left and right hotends have identical structures and materials, and can be used interchangeably.

Because H2D is a dual-hotend printer, and in the most extreme scenario, all AMS can be connected to one hotend while the other hotend uses an external spool holder, it can support up to 25 colors.

The first-generation AMS has been confirmed to have full plug-and-play compatibility and can be used with the H2D for multi-color printing, but it does not support the AMS drying function.

Due to the fundamental differences in the feeding mechanism and buffering structure, the H2D does not support the AMS lite.

The two 4-pin ports on the back are reserved for future expansion accessories. For example, to upgrade a non-laser version of the printer to a laser version, one of these ports can be used to connect an external air pump.

Although the hotend of the H2D series is similar to the A1 hotend in structure , it is not exactly the same.

The H2D hotends are specifically designed for the H2D printer, offering optimized compatibility. For example, they support a larger maximum volumetric flow rate, lower clogging risk, more precise nozzle offset calibration between the left and right hotends, and automatic hotend type recognition via the live camera. Therefore, to ensure optimal print quality, it is strongly recommended not to use A1 hotends on the H2D printer.

Therefore, to ensure you get the best print quality, we strongly recommend that you do not use the A1 hotend for H2D printers.

Purchasing additional H2D hotends for use on A1 printers is feasible. However, you will also need to use the H2D hotend silicone sock.

Both the 10W and 40W laser modules are blue light lasers that support processing a variety of materials, including wood, rubber, metal sheets, leather, dark acrylic, and stone. However, due to differences in power and size, there are the following distinctions:

1. Maximum cutting thickness(For Basswood Plywood):

10W laser module: 5mm;

40W laser module: 15mm;

2. Maximum engraving speed(For Basswood Plywood):

10W laser module: 400mm/s;

40W laser module: 1000mm/s;

3. Processable Area:

10W laser module: Maximum processing area X310mm * Y270mm, maximum processing height 280mm;

40W laser module: Maximum processing area X310mm * Y250mm, maximum processing height 265mm;

The package does not include a standard USB flash drive. You can still initiate printing normally without a USB, as the printer has built-in storage space to run print files.

However, without a USB inserted, the following functions will be affected:

1. The recording and time-lapse photography functions can't be turned on;

2. Printing cannot be initiated through the LAN;

3. Print files cannot be sent to the machine for storage through the studio;

4. Log files cannot be exported;

USB requirements: USB2.0 protocol or above (actual minimum write speed needs to be greater than 10M/s), supported file formats are FAT32 and exFAT. And the printer only supports mounting one USB, and cannot connect multiple USB via a USB hub.

The hotend to be used for printing has already been determined when the model file is sliced. As for the built-in models, the right hotend has been selected during the slicing process, so it is impossible to change the hotend used for printing on the printer screen.

When you slice the file in Bambu Studio and send the print task , you can freely choose to use the left hotend or the right hotend. For some filaments, such as TPU and PPS/PPA-CF, it is recommended to use specific hotends for printing.

For more details on H2D filament printing, please check the Wiki.

H2D is equipped with an efficient exhaust system that effectively removes smoke and dust generated by laser operations, significantly reducing contamination. During R&D, we conducted rigorous testing to ensure that with regular machine cleaning, the impact of smoke and dust on performance and precision is negligible. For detailed cleaning instructions, please refer to: Wiki.

Due to the flexible nature of TPU filaments, there are some operational issues that can arise during feeding and printing. To facilitate TPU printing, we have created a dedicated Wiki guide. Simply follow the instructions in the Wiki to successfully print with TPU filaments: Wiki.

Because laser processing involves using high-energy lasers on potentially flammable materials, we strongly advise users not to leave the machine unattended during laser operations. Please maintain constant vigilance over the machine's operational status and ensure that there are no flammable or explosive materials in the machine's surroundings. For more information please refer to: Wiki.

For more information about H2D, refer to the official Wiki.