2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

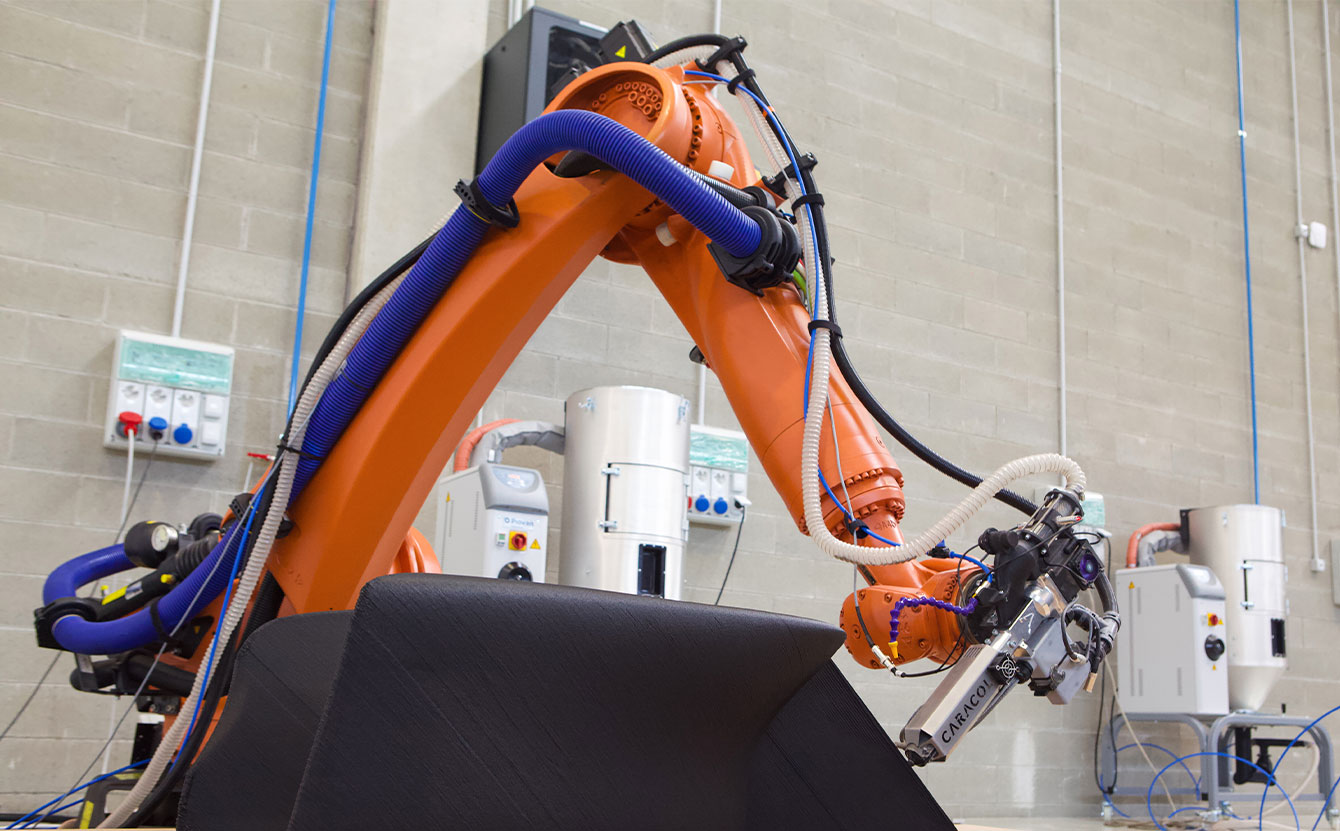

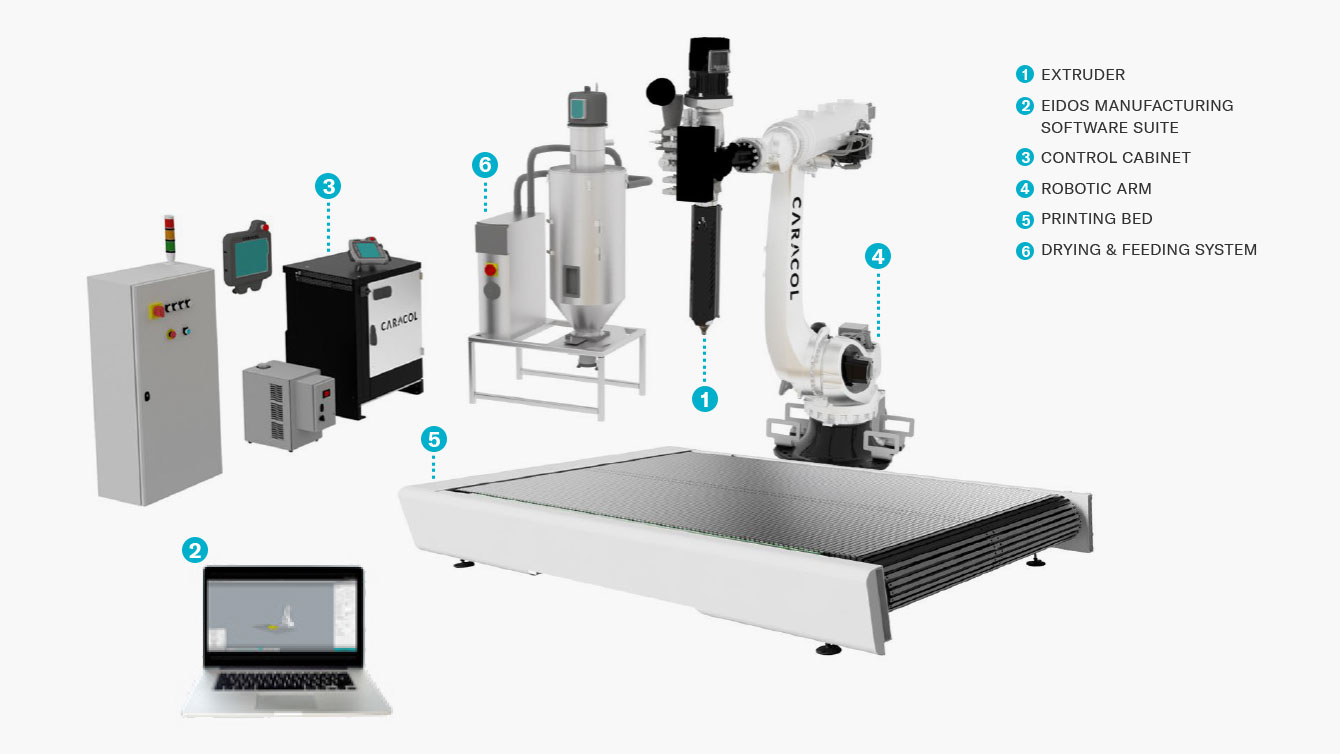

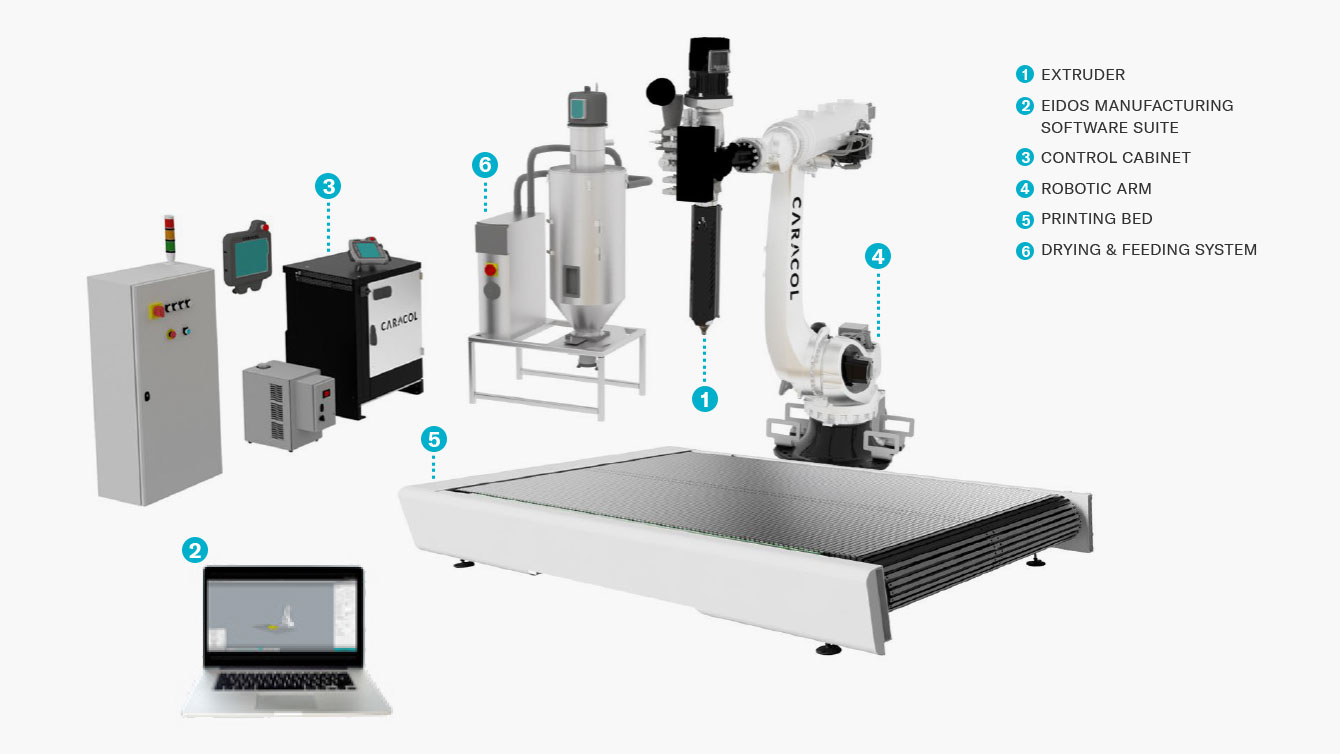

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing NowCaracol Heron AM is a large-format additive manufacturing system featuring a robotized extrusion head with continuous feeding of composites and polymers. This turnkey platform can be modularly configured according to the specific applications and materials to print; it includes dedicated software for complex tool paths and integrates various features for producing advanced industrial parts.

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Contact us for detailed purchasing support and custom pricing. A Dynamism 3D Printer specialist will contact you within one business day.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Print bigger, print better with Heron AM

Caracol Heron AM is a large-format additive manufacturing system featuring a robotized extrusion head with continuous feeding of composites and polymers. This turnkey platform can be modularly configured according to the specific applications and materials to print; it includes dedicated software for complex tool paths and integrates various features for producing advanced industrial parts.

Flexibility is freedom in customizing parts’ design and geometries.

Efficency means optimized lead times and lower costs, without compromising quality.

Sustainability of the production process, aiming for a zero-to-positive impact, by enabling circular economy, cutting waste, and using recycled materials.

With end-users in mind, Caracol develops its LFAM technology platform to expand the potential of additive manufacturing on large, complex, industrial applications. The aim is to meet the most demanding industrial requirements and quality criteria, supporting clients in fully leveraging their machines with an extensive set of services across applications.

Set up the system around your manufacturing needs, to be flexibly integrated in your shop floor.

6+ axes industrial robotic kinematics allows Heron AM to 3D print parts with complex geometries and to extend the printing volume according to the arm’s reach or by placing the robot on a rail or plinth.

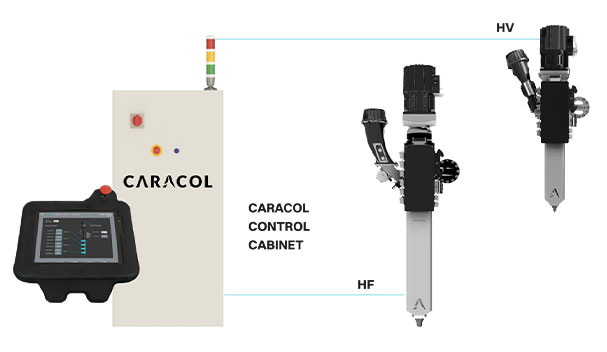

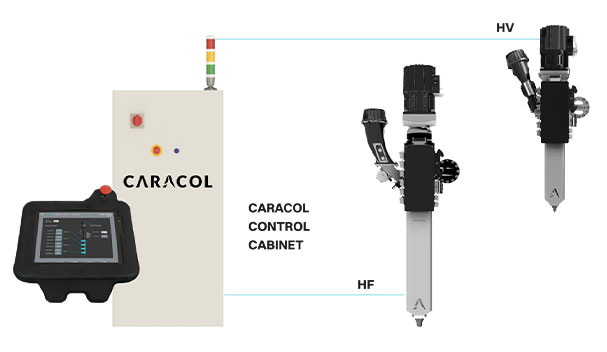

Caracol develops high performing robotic extruders to guarantee the best processing of a wide range of fiber-filled thermoplastic pellet materials. According to the specific requirements and applications you need to cover, you can choose the best extruder to achieve precision, flexibility, throughput, and efficiency.

High Accuracy (HA)

Light and compact, to provide agility and precision.

High Versatility (HV)

Flexible, to cover a broad range of applications and diverse industrial needs.

High Flow (HF)

Robust, to assure quality and efficiency with an extensive range of materials.

Caracol’s software suite integrates hardware to enhance full control and flexibility on Heron AM.

Parameters & Path Planning to easily set the printing parameters, develop and simulate the slicing.

IoT Platform with cloud smart monitoring to ensure full control of the machine, process quality and repeatability.

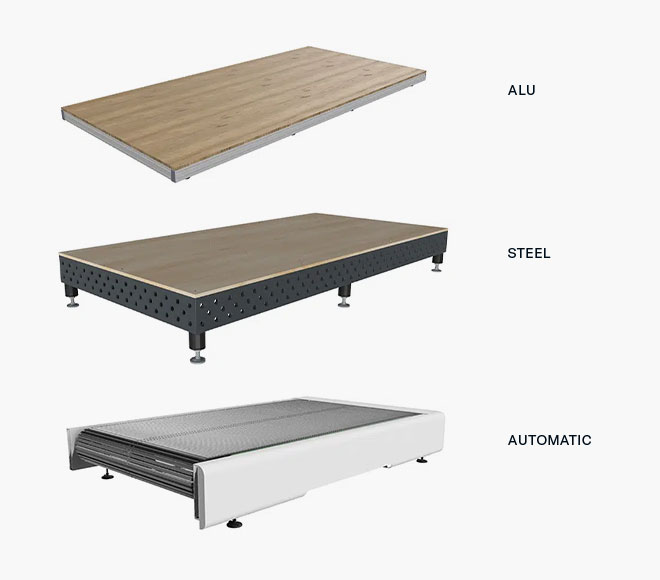

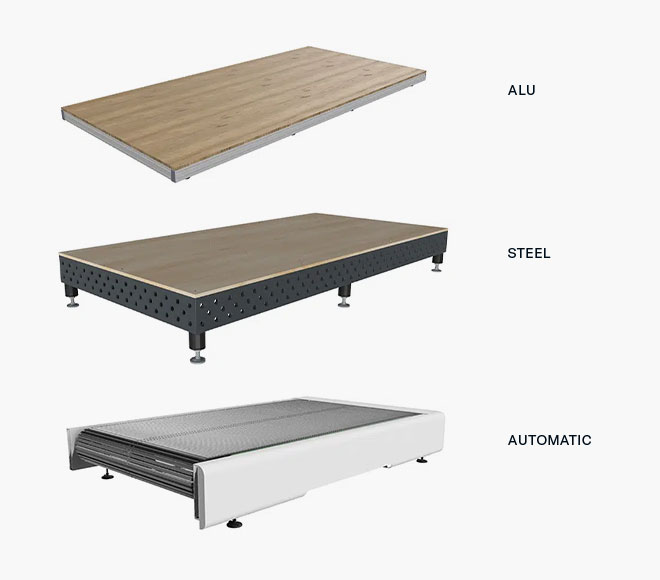

A key element for successful production, each printing bed is developed to fit specific manufacturing needs and is customizable in size.

ALU aluminum frame structure with MDF top panels ensuring stability throughout the job.

STEEL bed with interchangeable top panels (MDF, polymer, glass, …) providing high rigidity, planarity, and durability across jobs.

AUTOMATIC bed for unmanned part clamping and unloading, guaranteeing solid grip and continuous production of 3D parts.

These systems directly and continously supply material throughout the print job, avoiding manual operations, and ensuring pellet humidity and temperature are controlled for best performance and quality.

Perimetral protections and enclosures can be configured around the specific production space and manufacturing needs. This allows to control environmental parameters, ensuring best conditions, safety, process repeatability and quality.

Caracol industrial 3D printers work with a centralized control unit on multiple end-effectors and a user-friendly HMI, to provide smooth modularity and flexibility on all Heron AM platforms.

Our MATERIAL LAB studies thermoplastic composites to guarantee process repeatability on Heron AM, qualfying a broad range of advanced materials daily.

PP Polypropylene

COMPOSITE & RECYCLED

PP + 30% Glass Fiber

ABS Acrylonitrile Butadiene Styrene

COMPOSITE & RECYCLED

ABS + 20% Glass Fiber; ABS + Carbon Fiber; ABS + 20% recycled Carbon Fiber

ASA Acrylonitrile Styrene Acrylate

NATURAL & COMPOSITE

ASA NATURAL; ASA + 20% Glass Fiber

PETG Polyethylene Terephthalate Glycol

NATURAL, RECYCLED & COMPOSITE

PETG NATURAL; rPETG; rPETG + 20% / 30% Glass Fiber

PC Polycarbonate

COMPOSITE

PC + 20% Carbon Fiber

PEI Polyetherimide

COMPOSITE

PEI + 20% Carbon Fiber

PLA Polylactic Acid

BIOBASED & COMPOSITE

PLA; PLA + natural fibers (50% Cork / 20% Oyster / 40% Olive / 40% Pine / Coffee / Algae)

TPE High Strength And Flex Elastomer

NATURAL

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now