2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download nowJavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

Please note:

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Bambu Lab CF PLA - Black 1kg

Bambu Lab CF PLA - Black 1kg

Bambu Lab PLA Basic - Jade White 1kg

Bambu Lab PLA Basic - Jade White 1kg

Bambu Lab PLA Basic - Black 1kg

Bambu Lab PLA Basic - Black 1kg

Bambu Lab PLA Basic - Blue 1kg

Bambu Lab PLA Basic - Blue 1kg

Bambu Lab PLA Basic - Red 1kg

Bambu Lab PLA Basic - Red 1kg

Bambu Lab PLA Metal - Cobalt Blue 1kg

Bambu Lab PLA Metal - Cobalt Blue 1kg

Bambu Lab PLA Sparkle - Onyx Black 1kg

Bambu Lab PLA Sparkle - Onyx Black 1kg

Bambu Lab PC - Clear Black 1kg

Bambu Lab PC - Clear Black 1kg

Bambu Lab PAHT-CF - Black 500g

Bambu Lab PAHT-CF - Black 500g

Bambu Lab Support PA - Green 500g

Bambu Lab Support PA - Green 500g

Bambu Lab ABS - Black 1kg

Bambu Lab ABS - Black 1kg

Bambu Lab Basic PLA Bambu Green - 1kg

Bambu Lab Basic PLA Bambu Green - 1kg

Bambu Lab PLA Matte Scarlet Red - 1kg

Bambu Lab PLA Matte Scarlet Red - 1kg

Bambu Lab PLA Matte Ash Gray

Bambu Lab PLA Matte Ash Gray

Bambu Lab PLA Matte Charcoal

Bambu Lab PLA Matte Charcoal

Bambu Lab PLA Matte Ivory White

Bambu Lab PLA Matte Ivory White

Bambu Lab PLA Matte Marine Blue

Bambu Lab PLA Matte Marine Blue

Bambu Lab PETG-CF Black - 1kg

Bambu Lab PETG-CF Black - 1kg

Bambu Lab PETG HF Black - 1kg

Bambu Lab PETG HF Black - 1kg

Bambu Lab PETG HF White - 1kg

Bambu Lab PETG HF White - 1kg

Bambu Lab PETG HF Gray - 1kg

Bambu Lab PETG HF Gray - 1kg

Bambu Lab PETG HF Red - 1kg

Bambu Lab PETG HF Red - 1kg

Bambu Lab PETG HF Blue - 1kg

Bambu Lab PETG HF Blue - 1kg

Bambu Lab PPA-CF - Black 750g

Bambu Lab PPA-CF - Black 750g

Bambu Lab PPS-CF - Black 750g

Bambu Lab PPS-CF - Black 750g

Bambu Lab TPU for AMS Black - 1kg

Bambu Lab TPU for AMS Black - 1kg

Bambu Lab TPU for AMS White - 1kg

Bambu Lab TPU for AMS White - 1kg

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Serially connect up to 4 AMS 2 Pro & 8 AMS HT units together for a total of 24 filament spool printing

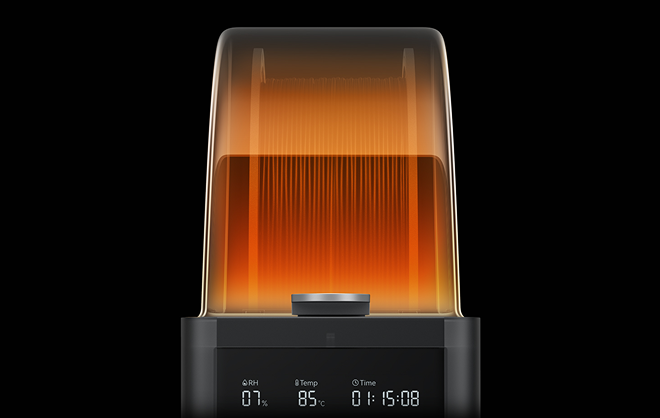

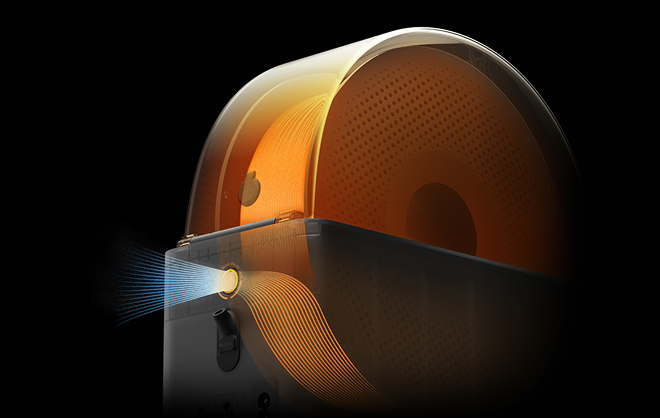

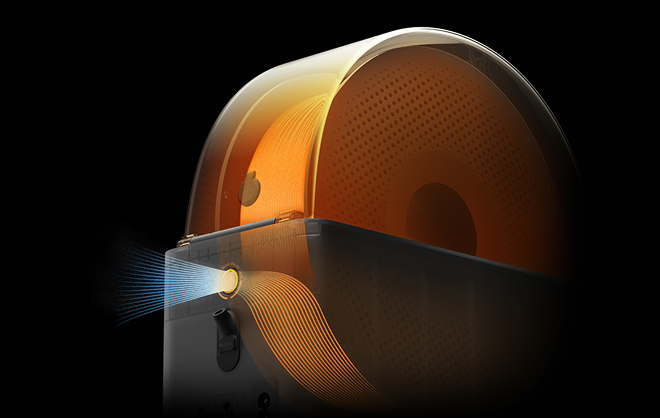

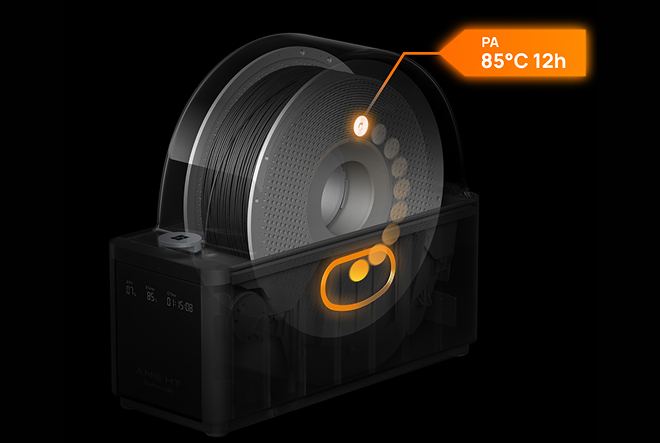

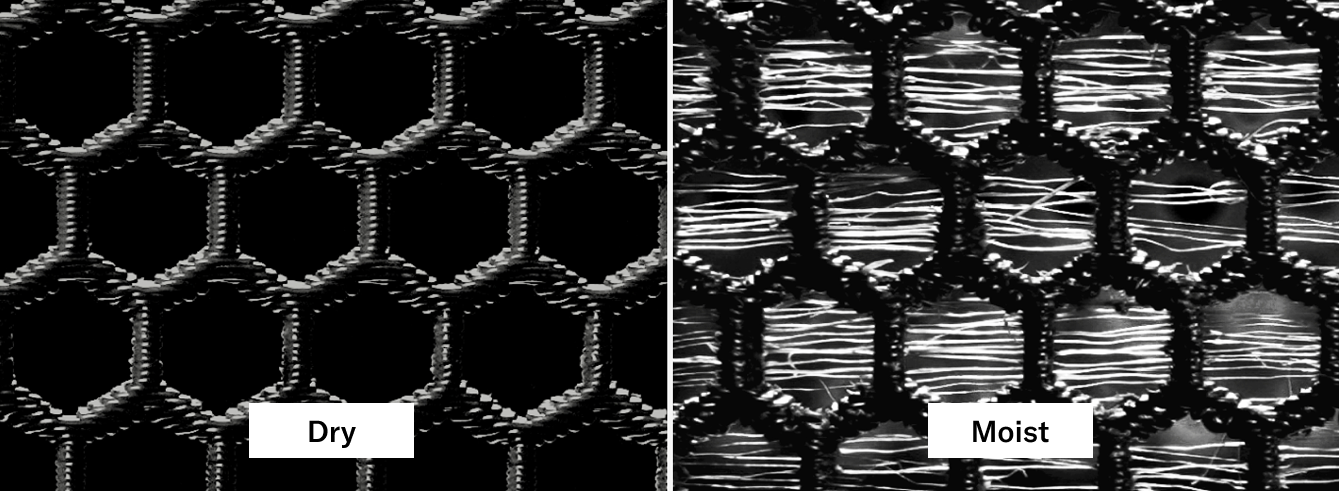

Fast filament drying & air-tight filament storage

Up to 85°C drying temperature

60% faster feeding speed

Drying temperature up to 85°C, optimized for high-temperature materials

Independent filament outlet designed for soft or brittle materials

Automated venting facilitates dehumidification during drying and airtight sealing for weeks of quality printing

During the drying process, the filament spools rotate automatically to ensure more even drying.

AMS HT uses RFID to auto-match drying settings for official Bambu filaments, no manual input needed.

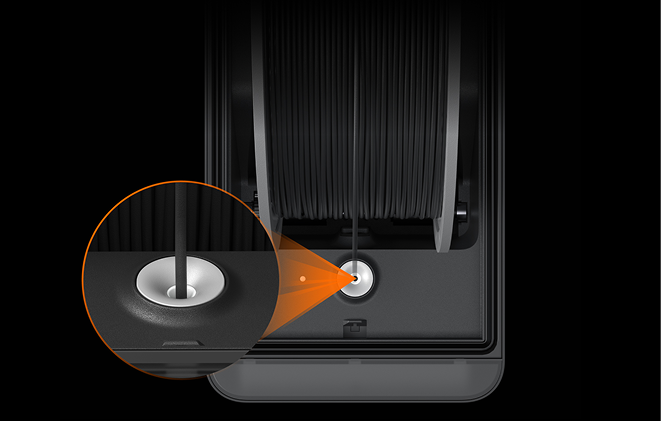

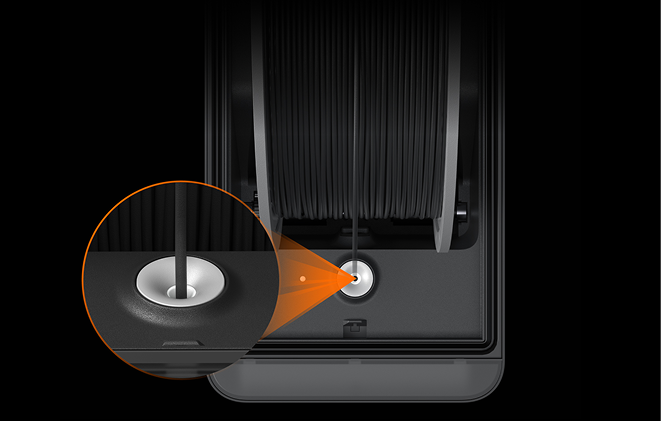

Ceramic filament inlets with Vickers hardness of 1200 significantly enhances durability.

Accurate temperature sensor and physical failsafe for precise heating.

Clear digital display for easy monitoring of drying status.

The AMS HT is compatible with all Bambu Lab products.

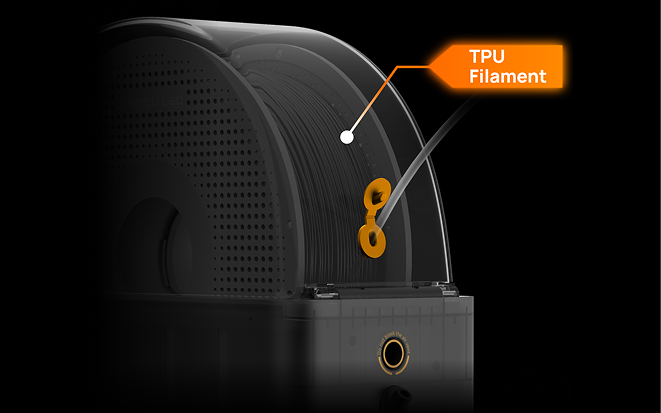

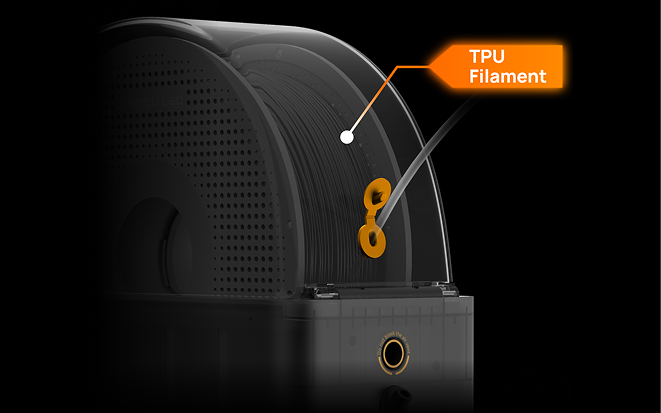

The port at the rear of the top cover is specifically for TPU filament. Due to the softness of the TPU filament, it is easy to fail when using the AMS 2 Pro automatic feeding function. When using the TPU, insert it into the AMS HT and ensure the material tray rotates in the correct direction. Insert the material tube into the TPU output port and manually push the filament through the PTFE tube until it is fully loaded into the extruder.

Note:

. When using TPU, AMS HT cannot use the automatic feed and return function, but can be used as a drying box to prevent material moisture.

. AMS HT won't be able to run filament drying while feeding filament and initiating a print via the bypass port.

AMS HT compatibility with X1 and P1 printers will be added through an OTA update by the end of April.

If only connecting one AMS HT to a X or P series printer, a filament buffer is required to be purchased separately. If connecting multiple AMS HT units,we recommend that you purchase an AMS Hub.

AMS HT compatibility with A1 and A1 mini printers will be added through an OTA update in Q3 2025.

Printing while drying is not yet supported, including all the AMSs that are related to the on-going print job (eg. The AMSs assigned for auto-refill). However, you can dry filament in AMSs that are not assigned to the on-going print job.

X1 and P1 series printers support up to 4 AMS HT connections at the same time.

H2D and X/P/A series printers are connected to AMS HT and use drying function. Each AMS HT requires an external 220V power supply for drying It is not supported to draw power from the printer for drying (The power adapter is pre-included with the product package).

When using the AMS HT drying function, the AMS HT must be connected to the printer via a 6-pin bus cable to ensure that the printer is powered on and set to filament drying mode.

The AMS HT cannot perform standalone drying without a connection to the printer.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now