2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

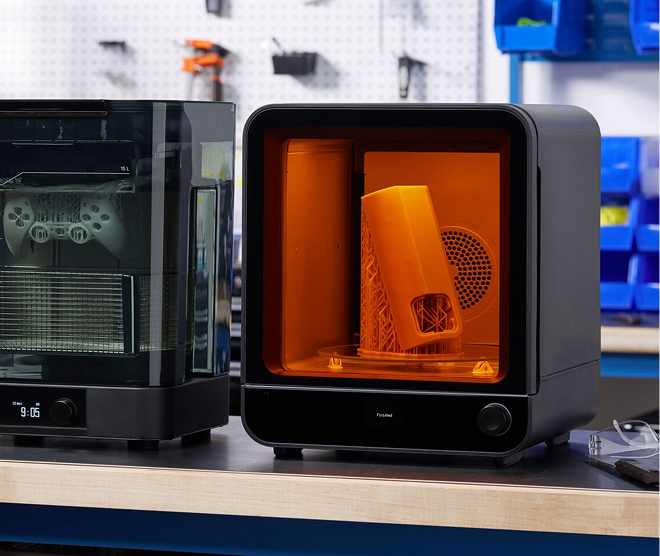

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing NowThe new Form Cure (Gen 2) post-cures parts 3-5x faster, with many parts reaching full cure in as little as 60 seconds.

Key Features:

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Stronger Parts, Less Effort

Form Cure automatically post-cures resin 3D printed parts after printing and washing, improving strength and performance. After washing, place parts into the Form Cure, close the door, and select your resin to begin curing at an appropriate temperature for a pre-configured duration. With the 2nd Generation Form Cure, many cure cycles are now as fast as one minute.

Advanced users can edit the cure cycle to ensure complex parts come out right every time, and can save their preferences with custom settings.

For biocompatible materials, curing is necessary to achieve the safety standards determined by regulatory agencies, and users should follow the indications specified for each material.

Form Cure is finely tuned to bring parts to their maximum

mechanical properties.

An advanced heating system precisely controls curing temperatures up to 80 °C

13 multi-directional LEDs emit the optimal wavelength of light for curing Formlabs materials

A rotating turntable provides uniform exposure during post- curing

For standard resins, simply use Form Cure’s default time and temperature. For all other materials, use unique recommended settings for optimum performance.

Form Cure's turntable rotates to provide uniform exposure.

The heating system preheats the chamber to get parts ready for optimum post-curing.

Once the chamber is heated, 13 LEDs trigger the post-curing reaction, bringing parts to their maximum mechanical properties.

Once time is up, parts are fully cured and ready for peak performance.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now