Automotive

3D Printing Solutions For

Applying Additive in Automotive

From prototyping to production to carbon fiber molding, discover how automotive and aftermarket part manufacturers are leveraging 3D printing to speed innovation while cutting costs.

Benefits of Bringing 3D Printing In-House

Design & Concept Validation

Verify form, fit, and function in days, not weeks, and for thousands of dollars less. As a result, move your project from concept design to final production faster than ever, reducing cycle times by as much as 50%.

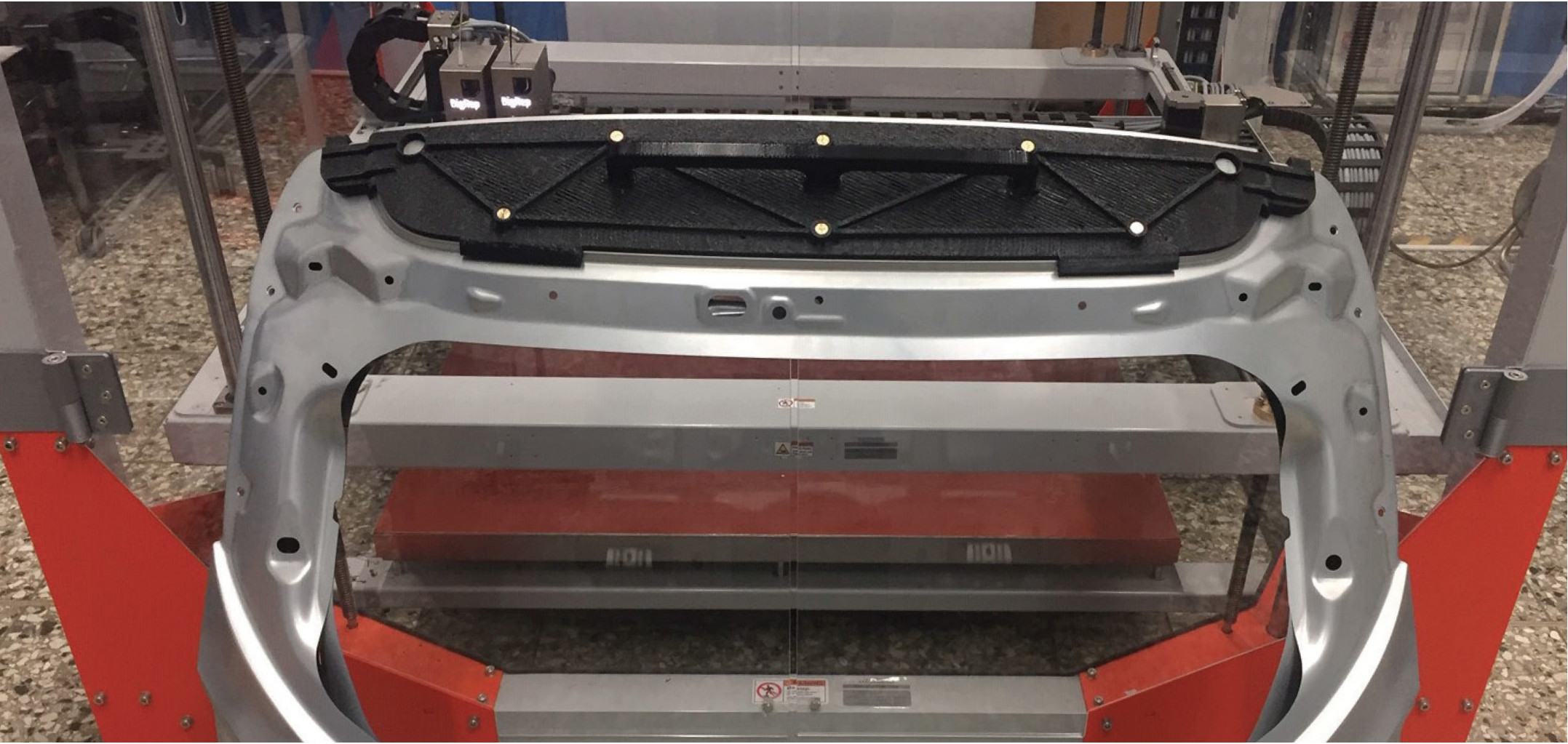

Manufacturing Efficiency

Reduce tooling costs and lead times with in-house manufactured jigs, fixtures, soft strong alignment features, and other manufacturing aides.

On-Demand Manufacturing

Transforming indirect material inventory into digital parts and reverse engineer obsolete parts that can be manufactured on-demand, reducing on-hand inventory while driving down part cost.

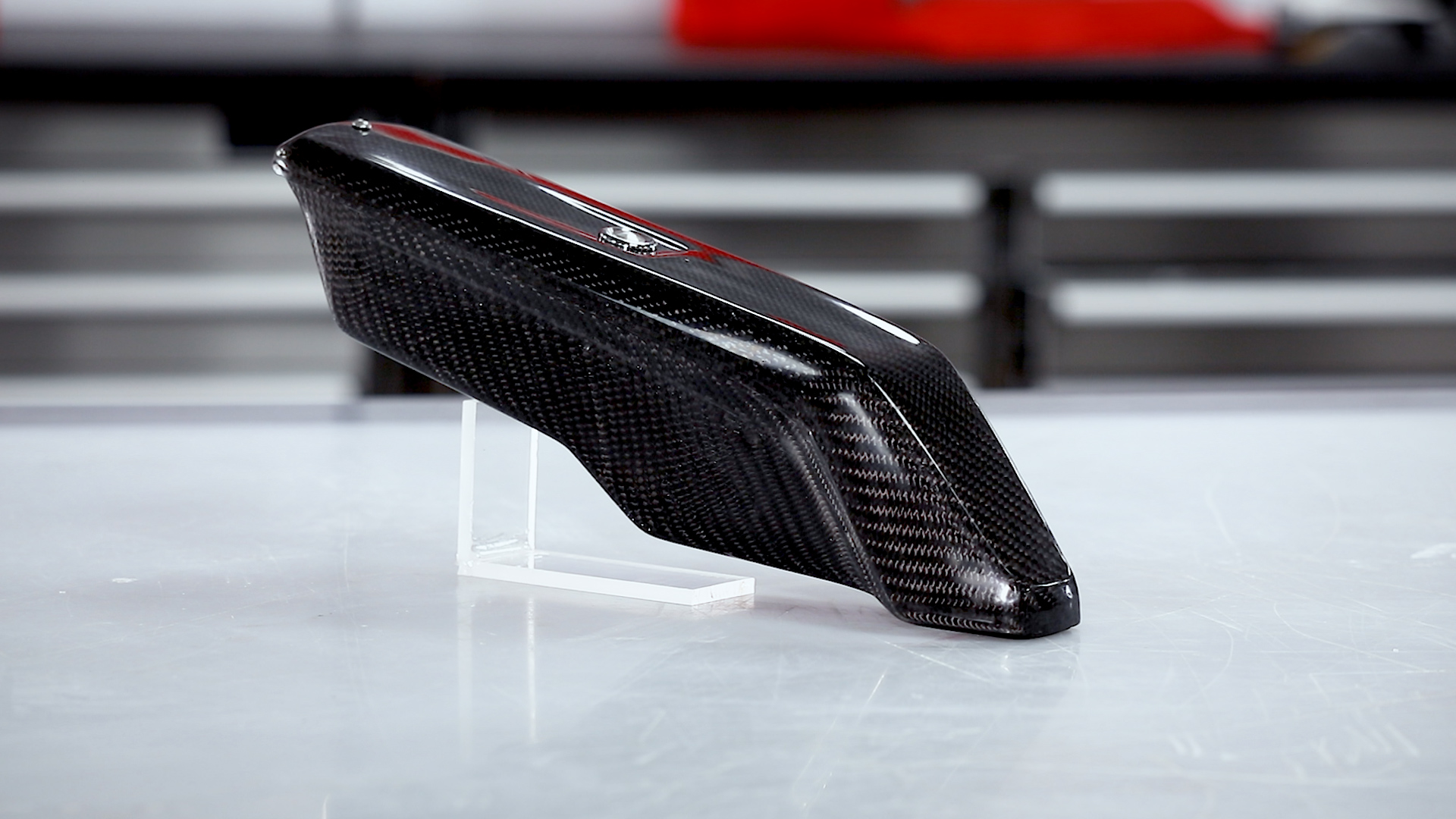

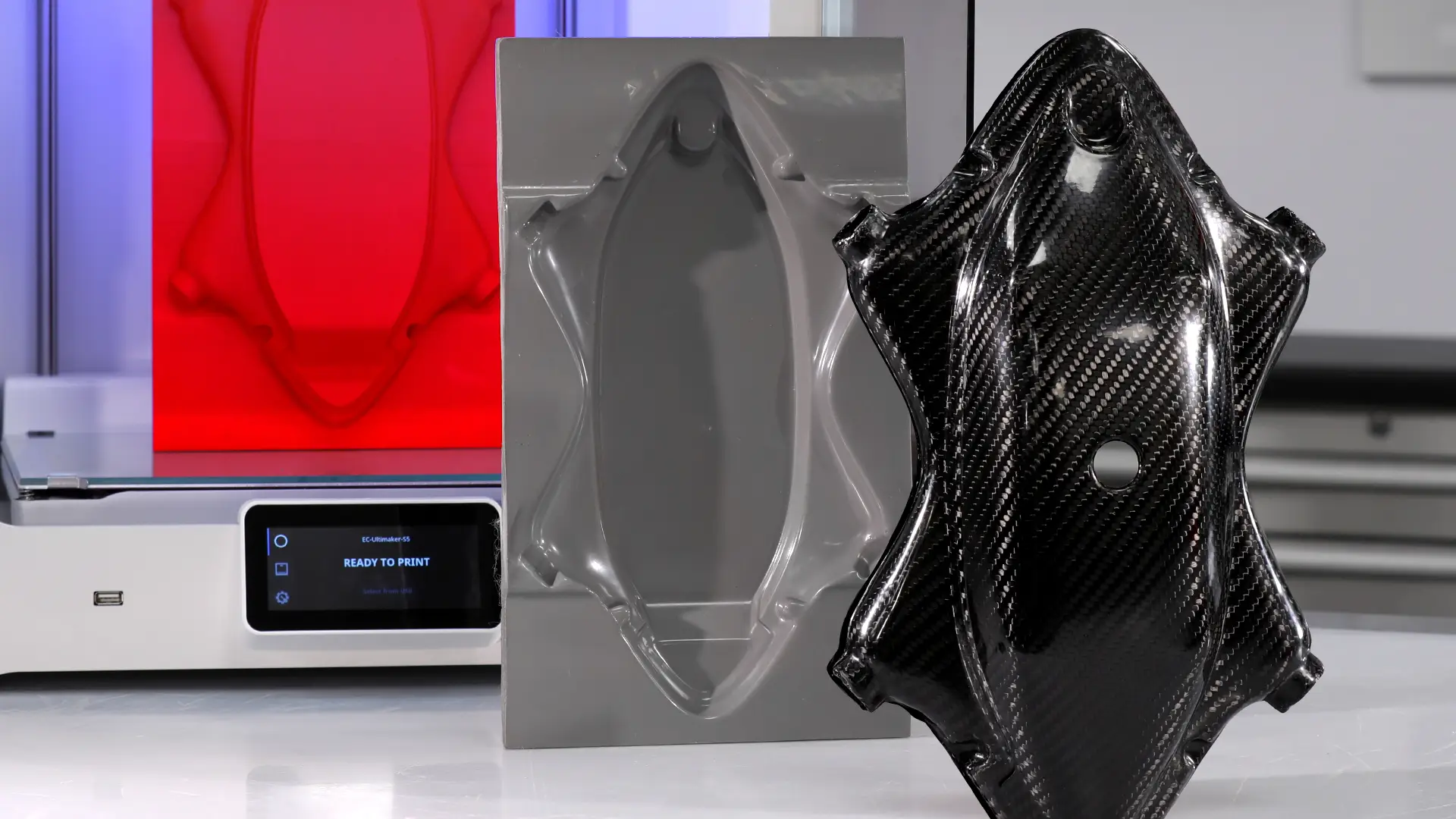

Carbon Fiber Molding

3D print carbon fiber molds, patterns, and sacrificial cores, producing fast, accurate results and complex designs without the need for handshaping or 5 axis CNC machining.

Selected Hardware For Automotive

Extra Large 3D Printers

Create large durable prototypes, jigs, and fixtures with up to 1m^3 build volume.

Metal 3D Printers

Create full metal components without the need for outsourcing or exhaustive hours of in house finishing.

Affordable Desktop Printers

Allow your engineering team to realize its full potential with affordable desktop 3D printers.

Discover More

Automotive Designers

Dynamism works with thousands of schools, companies, government organizations, and understands the challenges with acquiring, and deploying cutting-edge technology.

Just getting started? Know what you’re looking for? We’re ready to discuss requirements and help you make an informed decision about the products you need at the best price.