JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

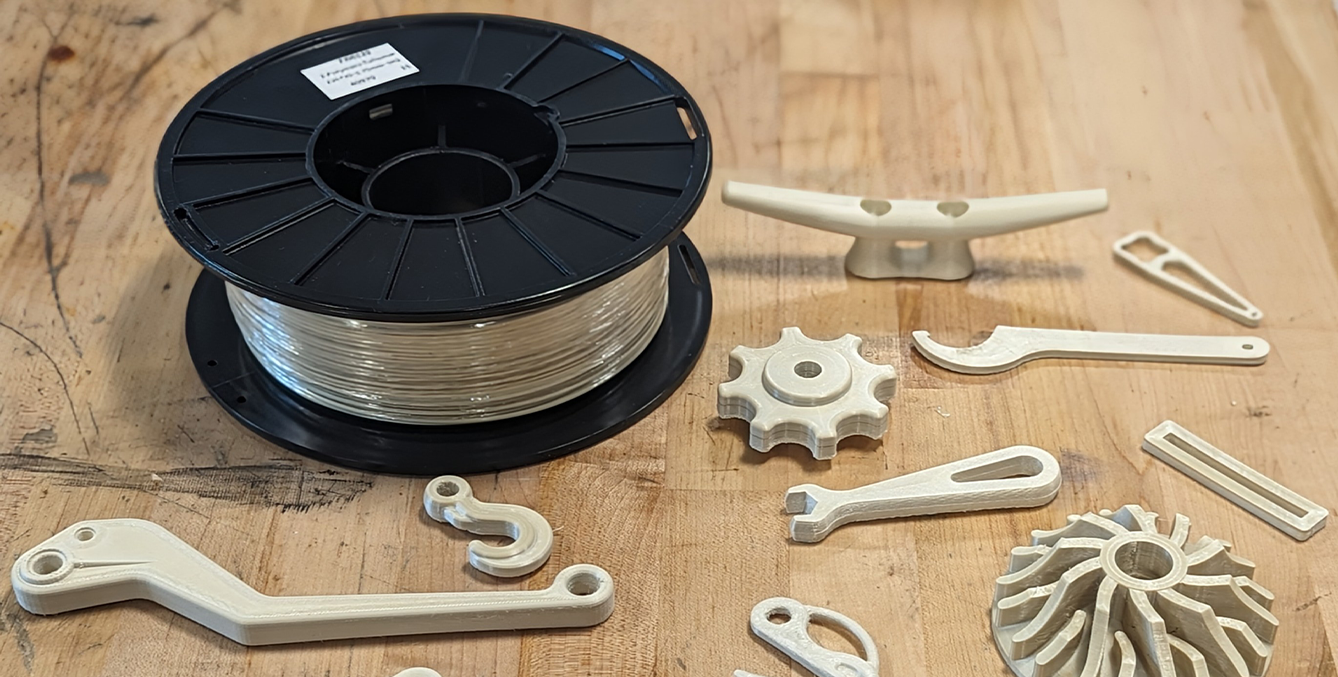

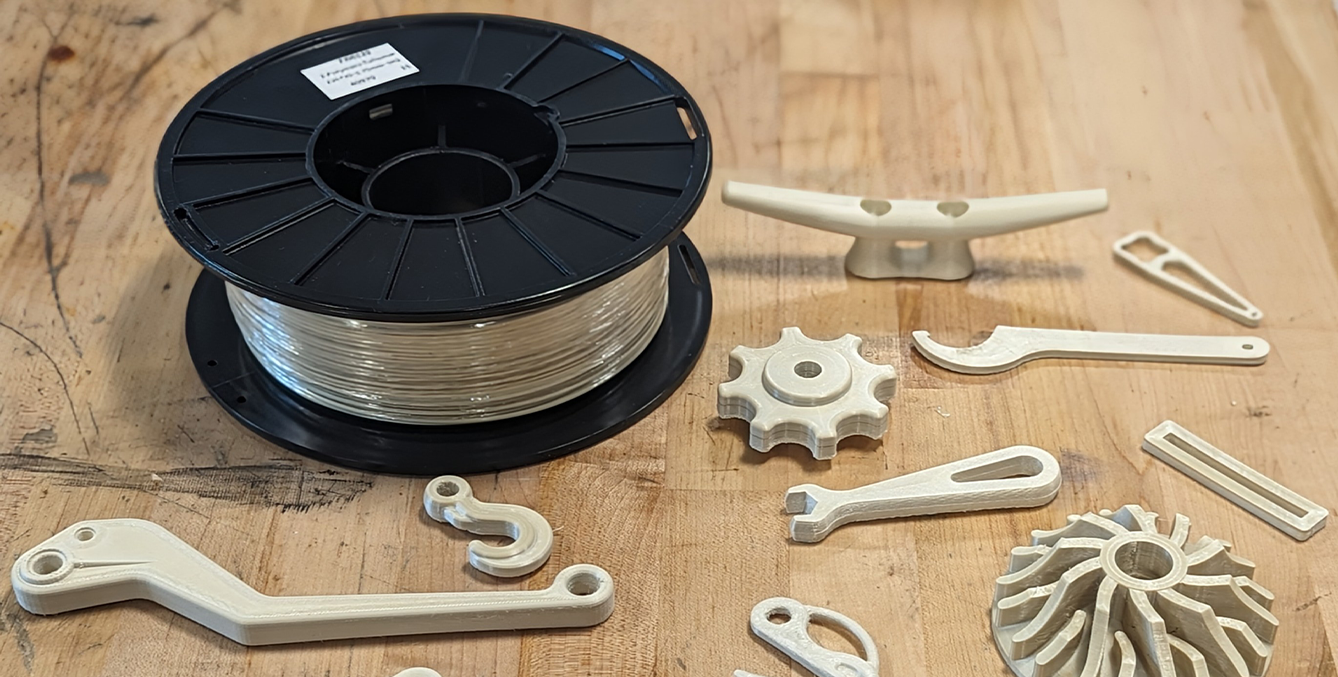

Z Polymers Tullomer - 1kg

Replacement for aluminum, steel, magnesium, PEEK, PEKK, PAEK, ULTEM, Nylon CF..

Key Features:

- Ultra lightweight

- High stiffness and strength

- Superior dimensional stability

- No need for annealing

Free US Shipping

International customers: please contact us for delivery options.

Tullomer Performance

Challenge

Bring Your Ideas

to Life

Submit your most ambitious applications for Tullomer filament, and you could win the chance to bring your vision to reality. Winners will receive Tullomer filament and a unique opportunity to collaborate with our team to showcase your project.

Enter NowErdos Miller Transformed MWD Tooling with Tullomer: Cut Costs & Boost Efficiency!

Download NowDont't Forget an Extended Warranty!

Low Price Guarantee

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

- Brand New

- Please contact us for international shipping options

- Free Shipping & In-stock verified orders before 3pm EST ship the same day

Who We Are

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

Our Company

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Customer Benefits

- White glove support

- On-site support options

- Training packages

Product Overview

Z-Polymers Tullomer 1.75mm Filament - 1kg

The Vision

Tullomer is a breakthrough superpolymer engineered to match the mechanical performance of continuous fiber-reinforced materials like PEEK, Ultem, and PC—without relying on fibers.

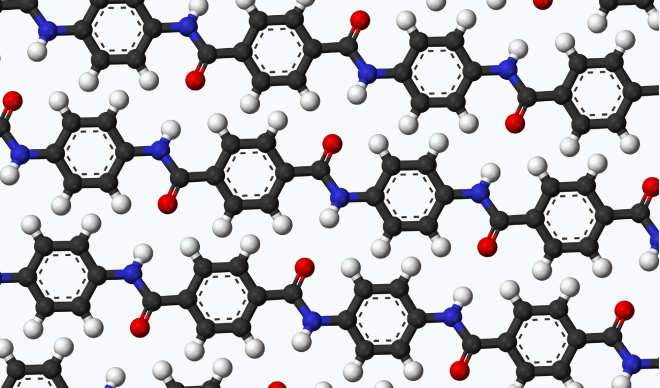

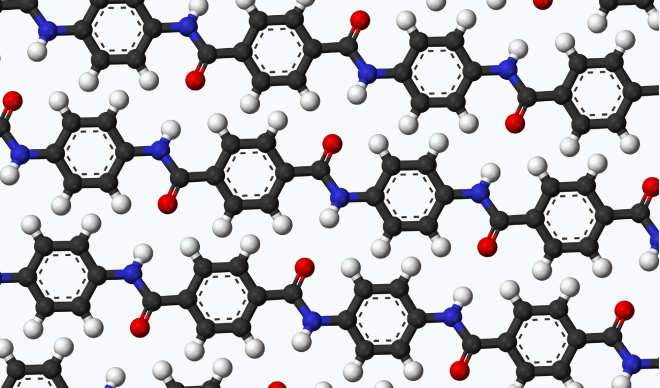

The Material Science

The key to Tullomer is the Mesogen Nematic Structures that line up in the same direction this alignment helps create strong fiber like properties. When the material is pushed through a nozzle the molecules stay lined up. This controlled alignment makes the material much stronger in the direction of printing.

The Strength Tullomer’s Molecular Structure Vs Other Super Polymers

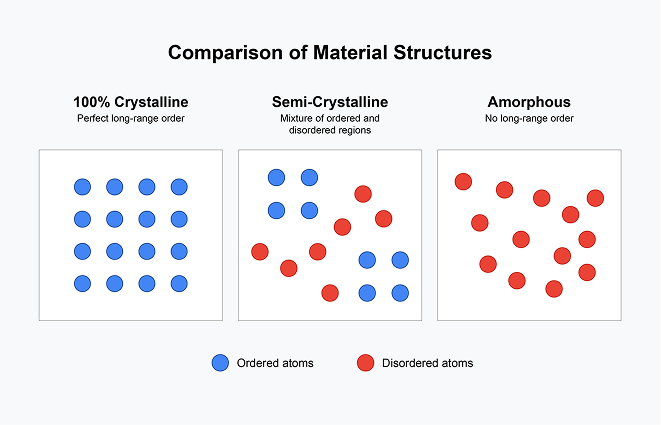

Tullomer is considered a 100% crystalline polymer, meaning its molecular structure is highly organized with a consistent repeating pattern, similar to the crystalline structure of metals. This crystalline structure is why it stands up to the performance of PEEK, Ultem & PC.

Key benefits & applications

Tullomer excels in mechanical strength, chemical resistance, and stability across extreme environments, outperforming PEEK, Ultem, and PC in fiber-like performance.

Printing Basics

Z Adhesion

Tullomer is strong and rigid in the X and Y directions, allowing control over part strength, even for complex shapes. Like most 3D printed materials, it is weaker in the Z direction due to layer bonding.

Recommended Tools

- Use textured or untextured build plates

- Thick steel build plate is recommended but not needed

- Must use a strong glue or adhesive Magigoo for PC is recommended

Recommended Print Settings

Nozzle

- Keep nozzle temperature around~275-300°C

- Start around 290°C and explore the effects of going hotter and colder.

- Tullomer viscosity drops the faster you extrude it, so going hotter is not always better.

- Z-adhesion is a challenge with Tullomer, and hotter temperatures help improve adhesion but require slower print speeds.

Bed Temperature

- Keeping bed temperature at 120C

- Keeping the part hot while printing is key to maximizing Z-layer adhesion and minimizing warping.

Mechanical Properties

- If you have a heated chamber, set it to 60°C or hotter if possible.

- Keeping the part hot when printing is key to maximizing Z-layer adhesion and minimizing warping.

Print Speed & Layer Recommendations for Tullomer

Recommended Settings

- Layer height: 0.050mm

- Wall speed: 500 mm/s (or as fast as your printer allows)

Key Considerations

- Faster print speeds and thinner layers improve fiber strength by applying more shear during printing.

- Z-direction adhesion is weaker than X-Y strength. Printing slower and with thicker layers can improve Z-adhesion but may reduce overall part strength.

Additional Tips

For Better Layer Bonding

- Use thicker line widths

- Experiment with thinner or thicker layers

- Increase nozzle and build chamber temperatures

- Print slower or adjust layer times based on part geometry

To Reduce Warping

- Use layers thicker than 0.1mm

Dynamism Digital Manufacturing

Dynamism Digital Manufacturing