2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing Now

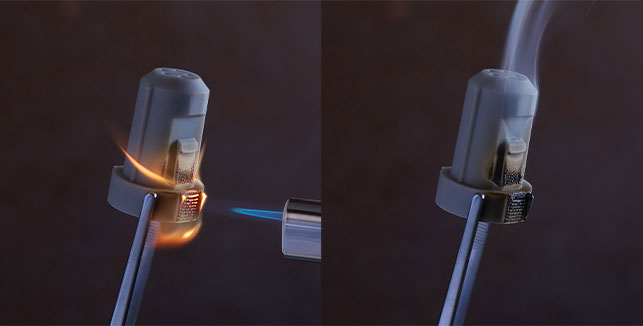

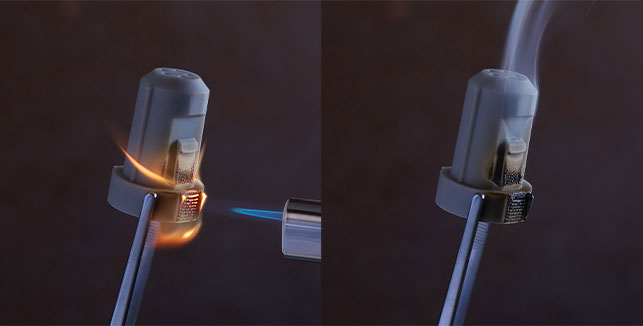

Dynamism Digital Manufacturing Fast and Professional on-demand 3D Printing Start Printing NowFlame Retardant Resin is ideal for printing heat-resistant, stiff, and flame-retardant parts. Self-extinguishing and halogen-free with a UL 94 V-0 certification.

Please Note: Compatible with Form 3, 3B, 3L and 3BL printers only.

Shop with Confidence

Dynamism will match a competing offer on qualified items. Learn More

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

Drive innovation more quickly, safely, and efficiently with Formlabs’ new self-extinguishing and halogen-free SLA material with a UL 94 V-0 certification and favorable flame, smoke, and toxicity (FST) ratings.

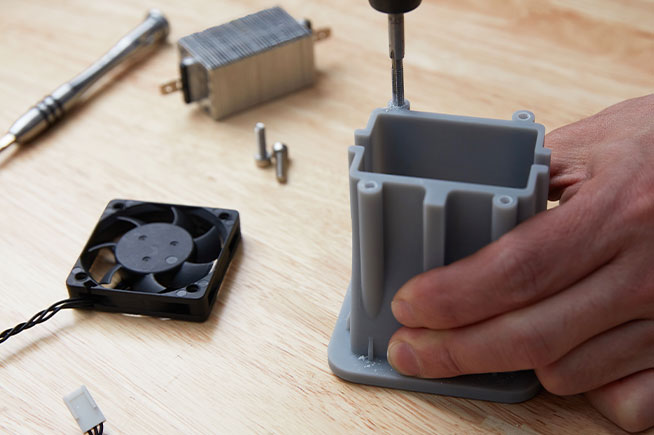

Use FR Resin to easily 3D print flame retardant, heat-resistant, stiff, and creep-resistant parts that will perform well long-term in indoor and industrial environments with high temperatures or ignition sources.

Accelerate time to market without the design constraints and upfront costs of traditional manufacturing with isotropic and highly detailed parts (XY resolution: 25um) with unlimited geometric freedom in any quantity (from 1 to 1000 parts) at any time.

Produce certified flame retardant, UL 94 V-0 and FAR-rated 3D printed parts that meet necessary certification requirements for enduring hazardous environments.

Parts will perform well long-term in indoor and industrial environments with high temperatures or ignition sources.

Fabricate plastic parts with exceptional surface finish far superior to other fabrication methods such as FDM 3D printing.

Produce stiff and functional parts with a 2.9GPa modulus that can handle post-fabrication operations such as tapping, trimming, and drilling.

Flame Retardant (FR) Resin is a cost and time-effective solution for fabricating self-extinguishing parts.

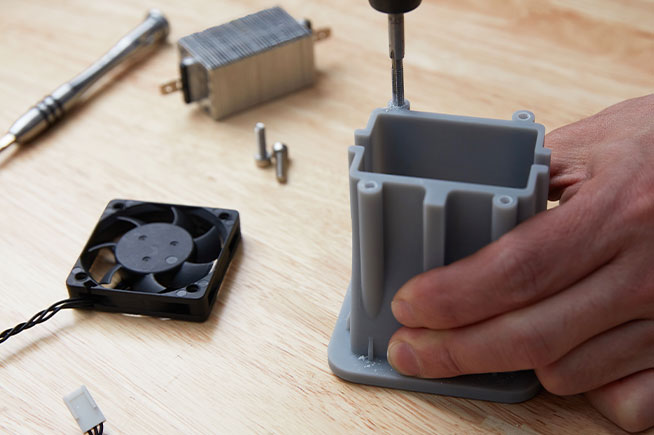

FR Resin is ideal for:

Interior parts in airplanes, automobiles, and railways with excellent surface finish

Interior parts in airplanes, automobiles, and railways with excellent surface finish

Protective and internal consumer or medical electronics components

Protective and internal consumer or medical electronics components

Custom jigs, fixtures, and replacement parts for industrial environments with high temperatures or ignition sources

Custom jigs, fixtures, and replacement parts for industrial environments with high temperatures or ignition sources

Heat Deflection Temperature 0.45 MPa

94ºC

111ºC

Heat Deflection Temperature 1.8 MPa

71ºC

83ºC

Tensile Modulus

2.9 GPa

3.1 GPa

Ultimate Tensile Strength

38.5 MPa

41.2 MPa

Elongation at Break

9.4%

7.1%

Notched Izod

22.1 J/m

22.4 J/m

10 min IPA or 15 min TPM

If washing with TPM, use a quick water rinse after to ensure full removal of TPM.

60 min

70 °C

There are two post-curing options for FR Resin. Refer to the technical data sheet to understand how different options affect mechanical properties, and choose the post-cure option that is best suited to the intended application. To achieve the highest HDT of 111 °C @ 0.45 MPa: Post-cure parts in Form Cure for 120 min at 80 °C. For applications that do not require the maximum heat resistance but offer more toughness, post-cure parts in Form Cure for 60 min at 70 °C.

Founded in 1997, we bring next-generation technology to customers, with an emphasis on expertise and white-glove service. Showrooms in Chicago, Detroit, Tokyo, and Seoul.

The leading national supplier of Desktop 3D printers. Expertise in both Industrial and Desktop 3D printing. Supplier of next-generation Metal, SLS, ultrafast Industrial printers.

2025 Edition Professional 3D Printer Buyers Guide

Choosing the right 3D printer doesn't have to be difficult. Find the perfect printer for your application. This in-depth guide covers pricing, materials, dimensional accuracy, and more.

Download now