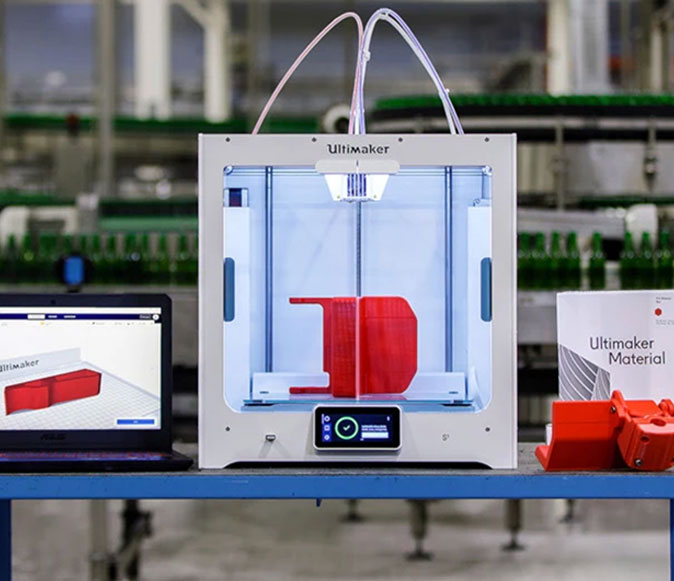

One of the best professional 3D printer brands just got better and bigger! Released today, the new Ultimaker S5 boasts a large build volume, intuitive touch screen, and reliable dual extrusion system. Already relied upon by tens of thousands of businesses, the launch continues Ultimaker’s dominance in the professional desktop 3D printing market.

Ultimaker S5 New Features

The Ultimaker S5 is a large leap from its predecessors with major changes across the board, delivering an easier and more reliable 3D printing experience. Here’s what’s new:

Build Volume: One of the most obvious changes is the spacious 330 x 240 x 300 mm build volume. In addition, the print area is now behind a set of tinted glass doors. These help to regulate temperatures during the printing process, minimizing warping and cracking.

UI/UX: The S5 features a new 4.7-inch (11.9 cm) full color touchscreen. An intuitive user interface enables users, both new and tenured, to easily control the machine, load filaments, run calibration sequences, and monitor prints, no experience required. In addition to the new touchscreen, Ultimaker added new automated leveling sequences to ensure perfect first layers and bed adhesion.

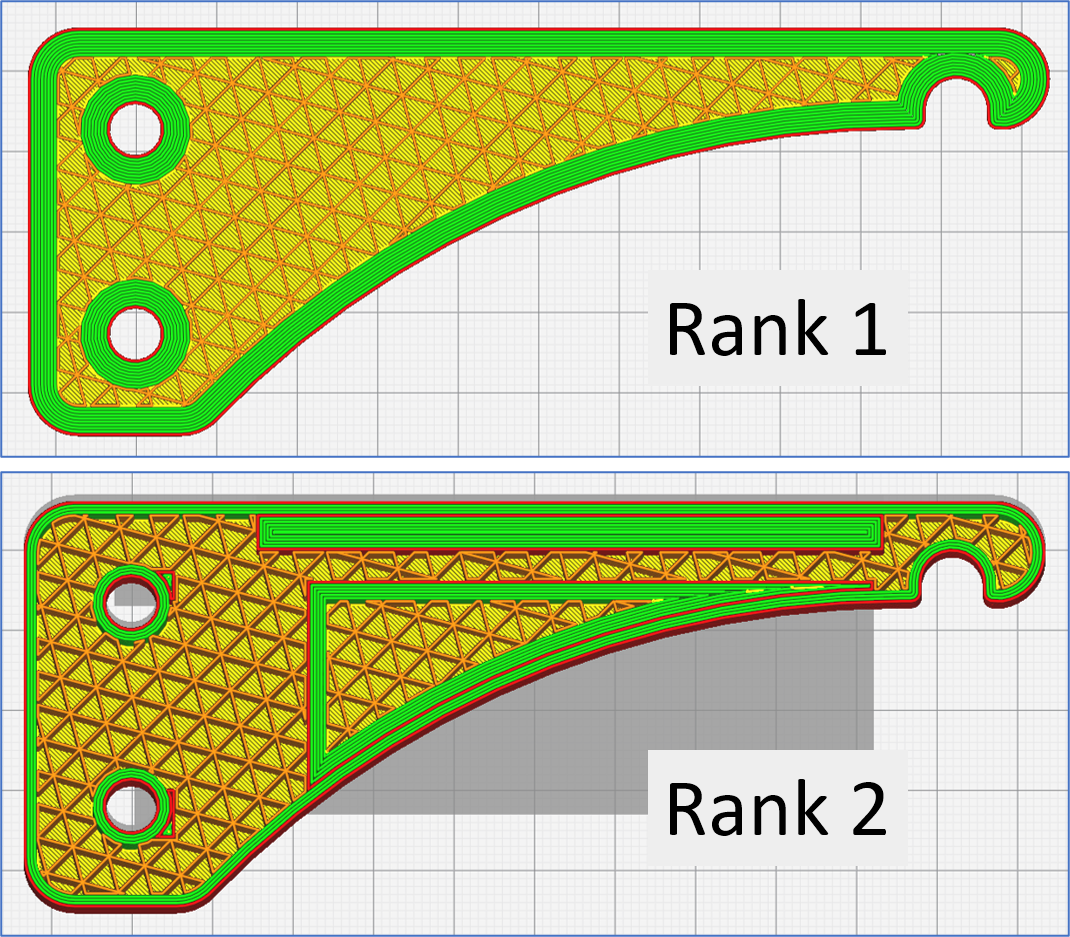

Connectivity: In an increasingly network connected world, the new S5 is no different. Onboard wifi and a built-in webcam seamlessly integrates with Ultimaker’s Cura Slicer, allowing users to easily send prints to the 3D printer from the comfort of their desk.

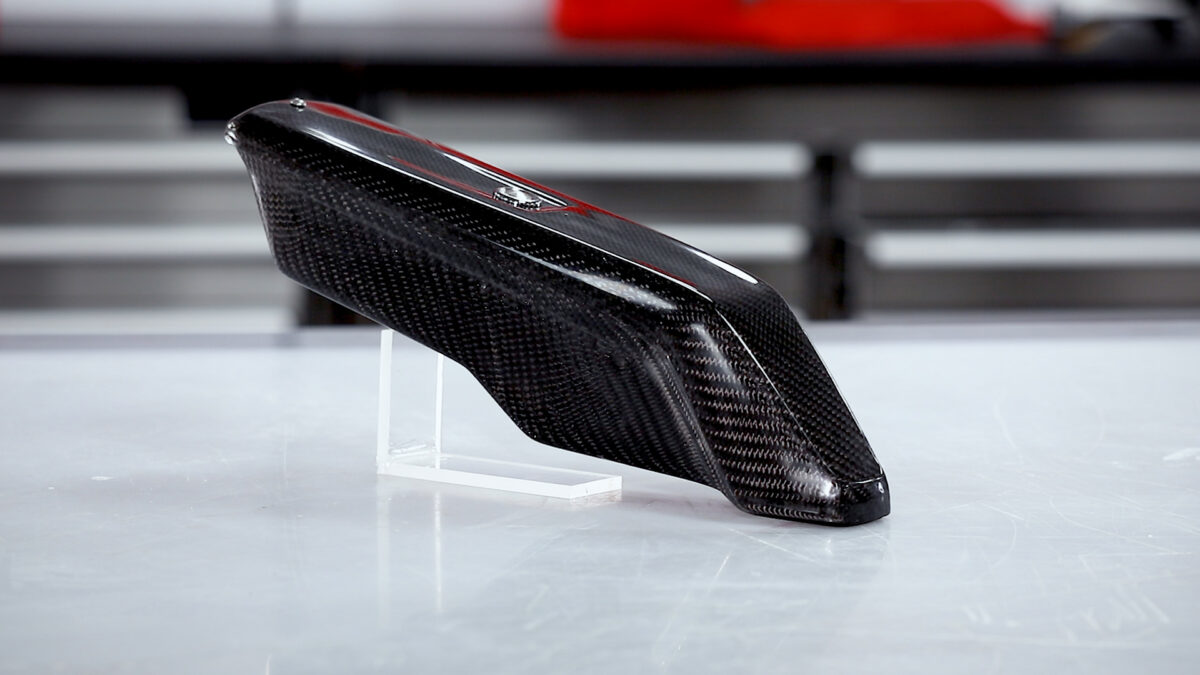

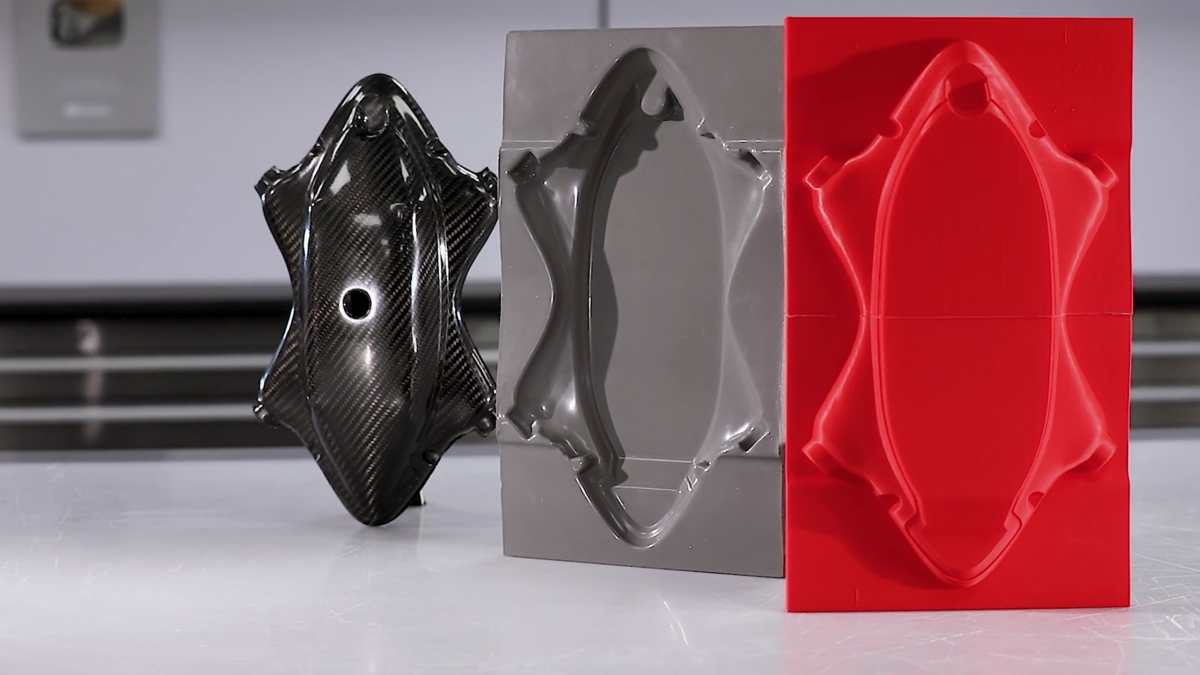

Materials: Included print cores enable the Ultimaker S5 to print an impressive range of materials out of the box. Going even further, the S5 now has an optional CC Red 0.6mm print core upgrade, enabling users to 3D print abrasive, high-strength materials, such as carbon fiber-filled and glass filled nylons.