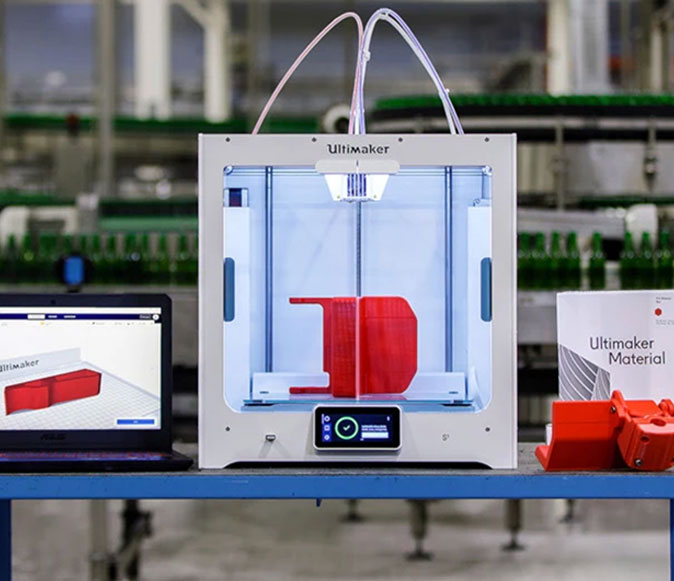

Dynamism, a leader in 3D printing solutions, announced their expansion into Industry 4.0 software with the addition of Teton Simulation’s SmartSlice, a Cura Slicing Software plugin that uses cloud-based Finite Element Analysis to optimize print parameters in order to create parts that meet performance requirements while reducing printing times and material usage. “As a leading provider of 3D printing solutions, it is important that we provide end-to-end solutions for professionals”, CEO Douglas Krone said, “this includes 3D scanners, materials, coaching from 3D printing specialists, and now software.”

Why businesses need Smart Slice – Less iterations, faster prints, and material savings.

When a part is 3D printed, there is a large amount of uncertainty in knowing if the part will perform as intended under end-use conditions. This leads to numerous build and break iterations resulting in excessive print times and wasted material. At the end of the day, this iterative process degrades two of the key advantages of 3D printing: reduced lead times and reduced waste. Combined with 3D printing’s recent massive growth in end-use applications, Smart Slice is poised to become an important solution for businesses wanting to increase their bottom line through applied 3D printing.

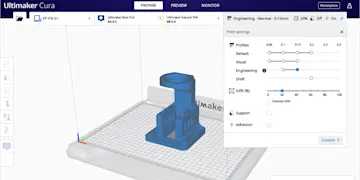

“Our SmartSlice technology was built from the ground up to give 3D printer operators near instant feedback on the viability of their project. There is simply no other solution in the industry that can provide lightning-fast, accurate feedback on the ‘as printed’ state of a part. Plus, our optimization feature takes the guesswork out of determining the right slicing parameters. We do all the work, so the user doesn’t have to. All of this capability is provided within the slicer making it very easy to use.” says Mike Kmetz – CEO at Teton Simulation Software.

Who Can Benefit?

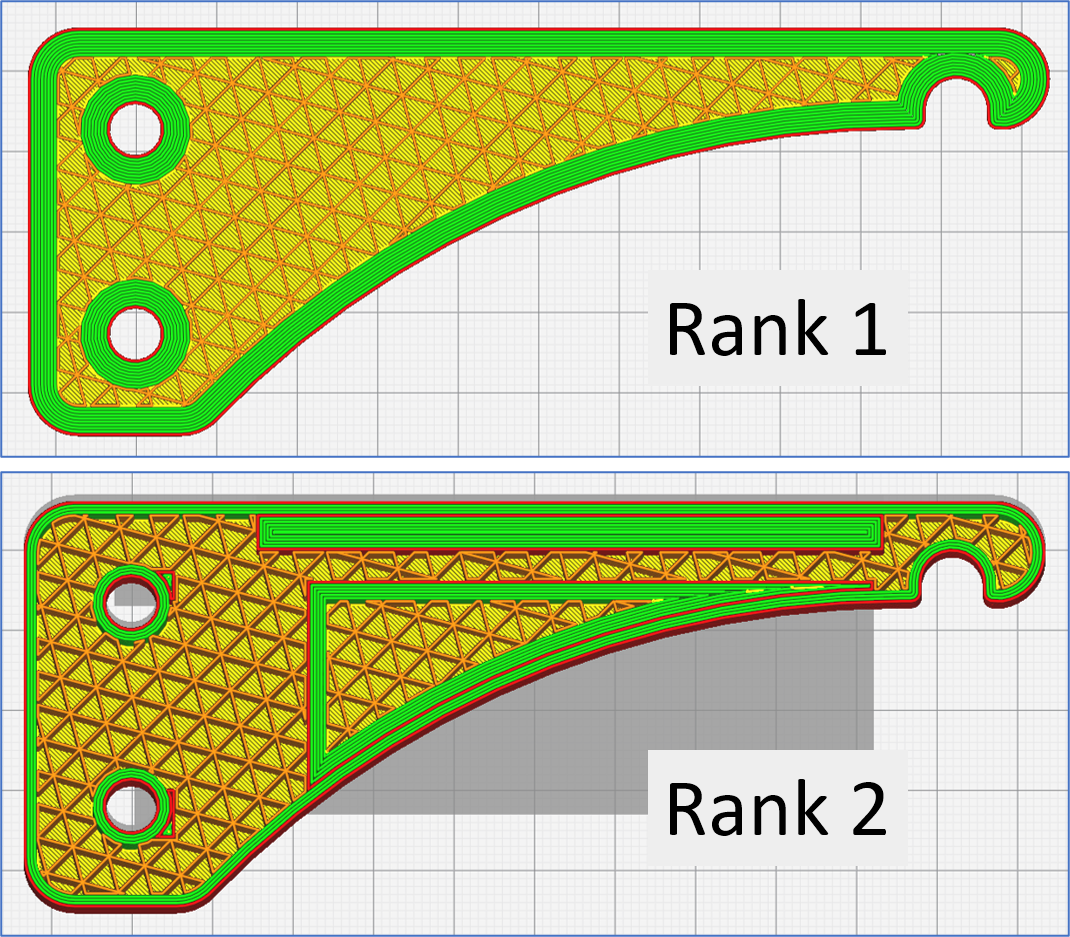

If you are using 3D printing for end-use parts, jigs and fixtures, concept validation, and/or manufacturing, SmartSlice’s part optimization is for you. Benefits are measured in days, material costs, and valuable engineering time both from failed iterations and straight print times for production parts. For example, in a test 3D printing a production run of 50 moderately sized levers, SmartSlice’s optimization was able to save 3.15 days in total print time per run while saving nearly 1kg of filament, all while delivering a part that met its performance requirements. For users unable to utilize cloud-based functionality due to IT limitations, local options are also available.

Want to give SmartSlice a try? Request a free trial.

“Teton's Smart Slice plugin brings engineering grade part simulation to Ultimaker Cura users. Using the integration options of our open and pluggable platform it will make sure parts still meet their engineering criteria, but need less material and therefore saving valuable time and costs. The cooperation with Teton and the integration of their innovative solution are a prime example of how we will be continuously adding value for our professional customers.” Paul Heijmans – Senior VP Software at Ultimaker.