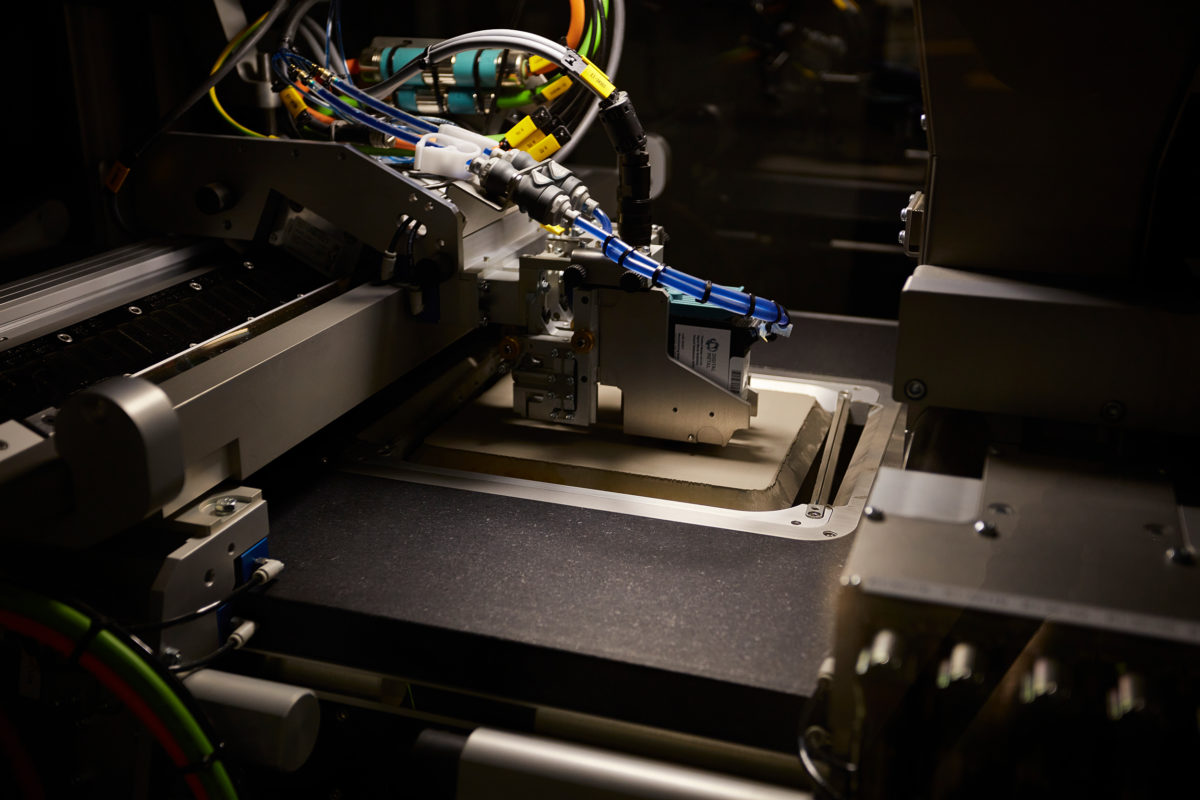

Maintaining an inventory of indirect machine materials associated with manufacturing and production can be essential to business continuity. Insert the “Take One, Make One” (TOMO) model, a new style of inventory management that leverages additive manufacturing and a digitized inventory of high wear-and-tear items to reduce physical inventory and machine downtime while streamlining parts supply.

Created by Azoth, a Dynamism customer and a member of the EWIE Group of Companies (EGC), TOMO transforms physical inventory into digital inventory that can be manufactured on-demand using 3D printing. Every time a replacement part is pulled from physical inventory and deployed for use, another is printed and stored for the next time that part needs to be replaced. The result: critical machine spare parts that traditionally would have taken six to twelve weeks to replace are able to be manufactured in hours or days.

I’ve seen processes that can have a hundred parts ready for you quicker than some companies can cut a purchase order, send it to their suppliers, and receive back into their system.

– Cody Cochran, General Manager of Azoth.

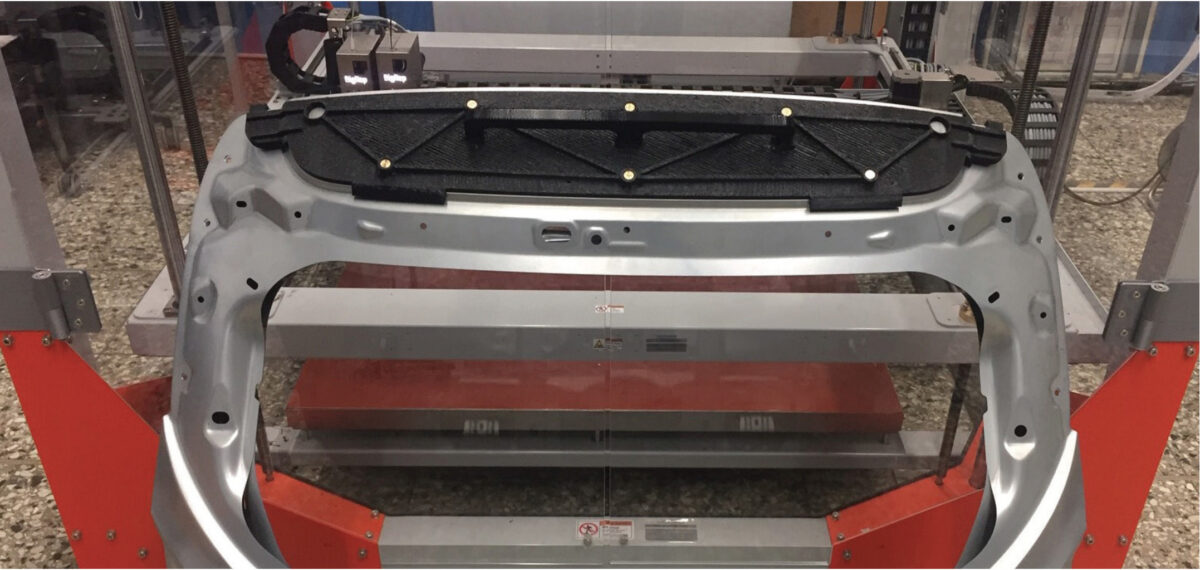

What parts are great candidates for the TOMO model? So far jigs and fixtures, gripper fingers, blow-off nozzles, and gage handlers have made ideal parts for moving to a digital inventory, although this is just the start. The TOMO model has much to be explored. Like traditional manufacturing tools, each 3D printing technology has unique traits, strengths, and weaknesses that make it ideal for different applications. Understanding additive manufacturing technologies and part requirements is one of the most significant hurdles to implementing TOMO. This is where Dynamism comes in, with a large selection and deep understanding of the various additive manufacturing technologies. For help selecting the right 3D printing technology, contact us here.