BigRep Pro vs Stratasys Fortus 900

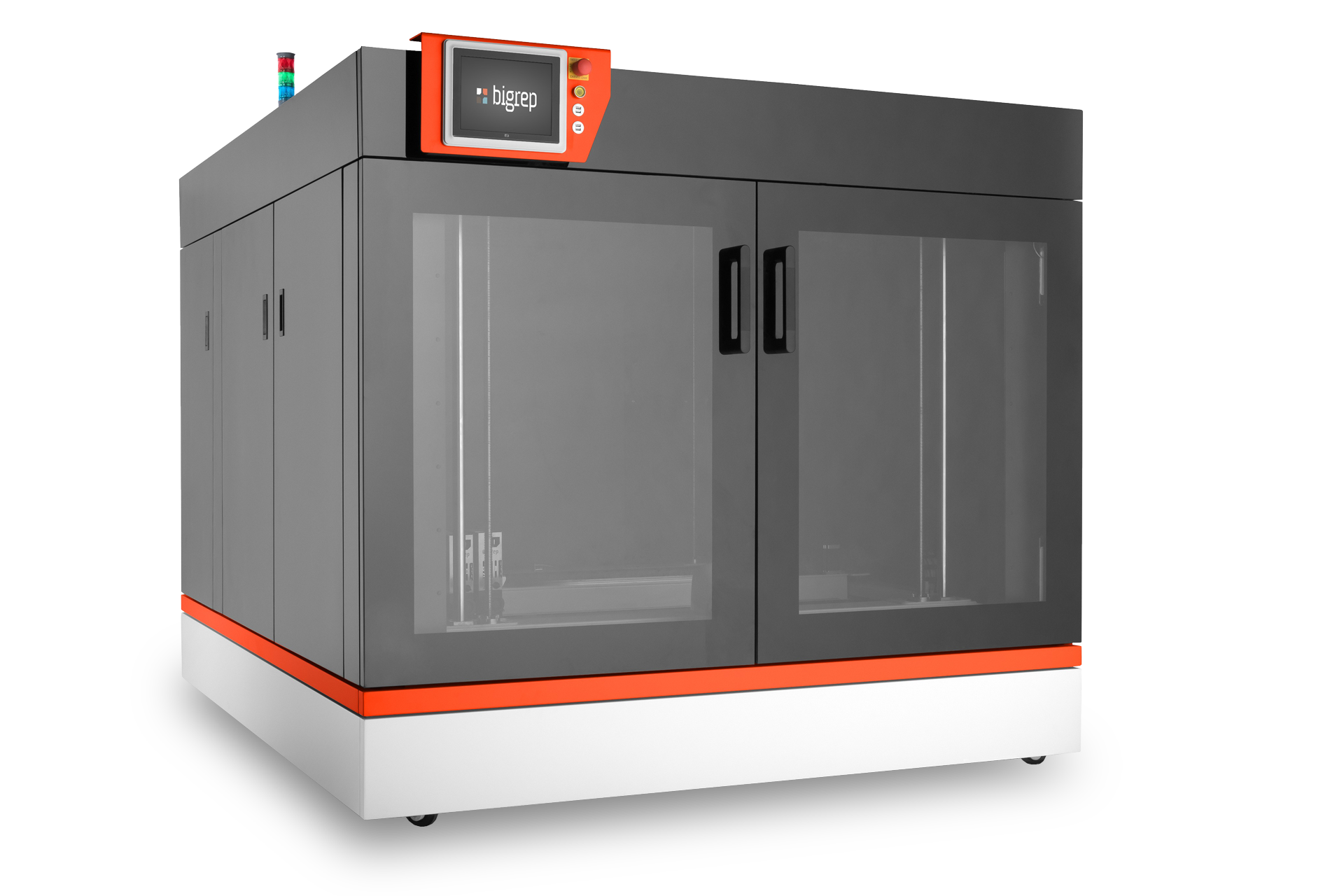

BigRep Pro

A large-format, industrial 3D printer with open, engineering-grade material format and powered by a state-of-the-art Bosch Rexroth CNC Control System.

Stratasys Fortus 900

Another large-format, industrial 3D printer with closed material system, which includes high-temp materials, but at a price tag over double that of the BigRep Pro.

The Basics

945 x 970 x 985 mm

Build Volume

Length x Width x Height

914 x 609 x 914 mm

3rd party material compatible; Plus BigRep certified ASA, ABS, PRO-HT, PETG, PA6/66, PRO HT, PETG, BVOH*

Available Materials

*More materials to come.

Propriety Stratasys materials only. ABS, ASA, PEKK, ULTEM, Nylon 12CF, water-soluble supports available and more

Varies based on material

(example ASA $102 / 2.3 kg)

Material Price

Comes with 1 material unlocked. Unlocking additional materials cost extra.

(example ASA $360 / 1.5kg)

0.1 mm – 1.2 mm

(Software configurable)

Layer Height

Note: Larger layer heights are recommended for extremely large prints.

0.127 mm – 0.508 mm

N/A

Connectivity

10/100 base T connection

Ethernet protocol.

$$

Price

$$$$

Hardware Breakdown

BigRep Pro

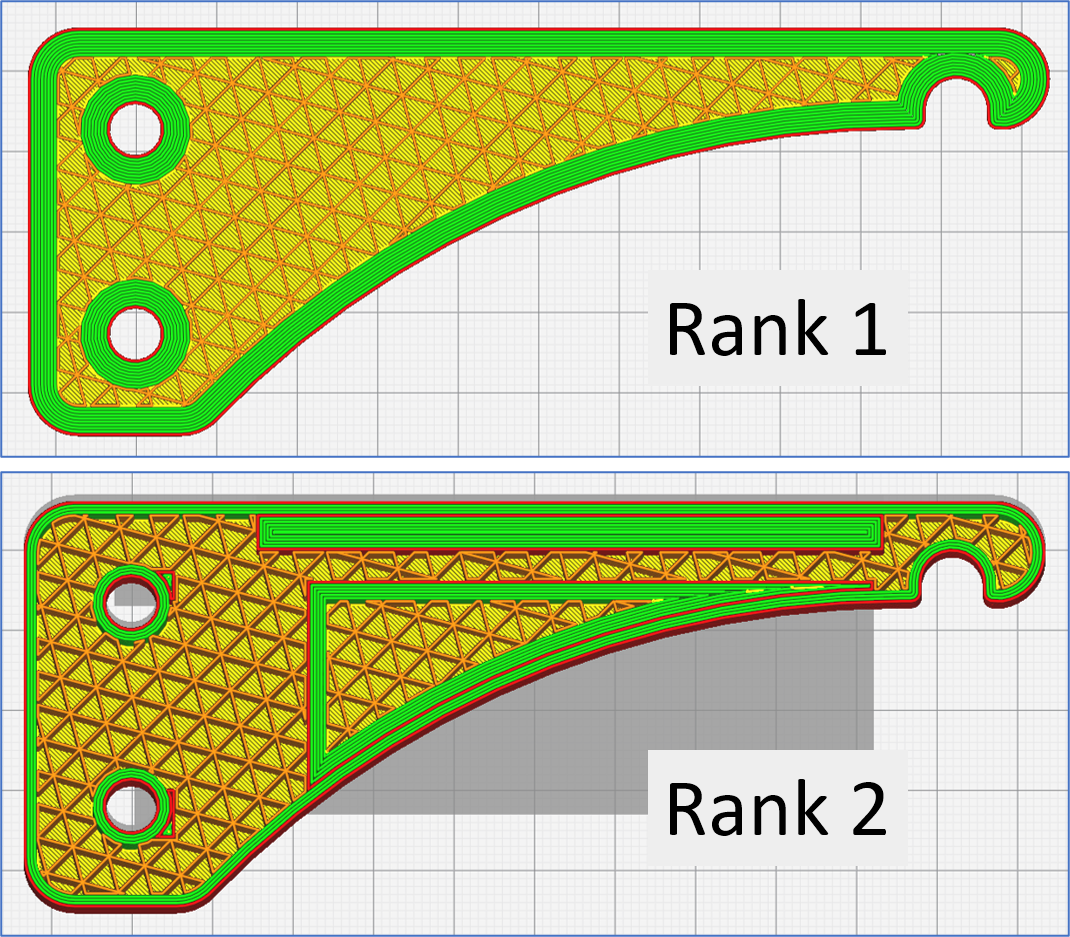

The BigRep PRO provides a slightly larger build volume, allowing users almost a full meter cubed build volume for both large parts or batches of smaller parts. Due to its high-quality industrial components, specifically suited for large-format additive manufacturing, the PRO is a dependable system for production, capable of running unattended 24/7.

Fortus 900

A large build area with proprietary materials provides a reliable 3D printing experience. Prospective buyers should consider if high-temperature materials, like PEKK and ULTEM, are a requirement due to the added price of the materials, material licenses, required service contracts, and additional cost of the hardware.